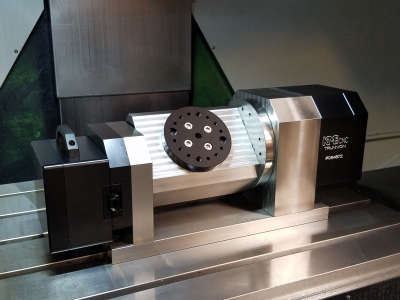

KME CNC announced that it has surpassed the company's wireless 5-axis tombstones with its new wireless 5-axis trunnions. KME CNC designs and manufactures American-made 5-axis systems that transforms current 3-axis and 4-axis machines to 5-axis production on virtually any machining centers.

"Constructed similarly to the standard trunnions, this compact unit is built out of meehanite cast iron and billet aluminum covers and provides the same benefits," Jerome Mel, senior applications specialist explained, "With its compact size it allows the operator to integrate the table on virtually any machine, i.e no size restriction without the hassle of cables. It is perfect for VMC with palleting tables and job shops that have high rate changeovers. Every industry can benefit from this compact unit."

Features of KME CNC's 5-axis wireless trunnion:

- Perfect application for palletizing VMC

- An easy to use system with no cables

- Ability to position parts for five sides machining

- Increasing operator's efficiency by reducing setup time

- Easy install on existing equipment with no additional drive cards

- Utilize existing space inside machine more efficiently

- Programmable directly through G code

- Excellent dimensions for various machine sizes

- 300 ft/lbs of torque on C drive up to 900 ft/lbs on A drive

Also, zero backlash for 10,000 hours of continuous use.

Contact Details

Related Glossary Terms

- backlash

backlash

Reaction in dynamic motion systems where potential energy that was created while the object was in motion is released when the object stops. Release of this potential energy or inertia causes the device to quickly snap backward relative to the last direction of motion. Backlash can cause a system’s final resting position to be different from what was intended and from where the control system intended to stop the device.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.