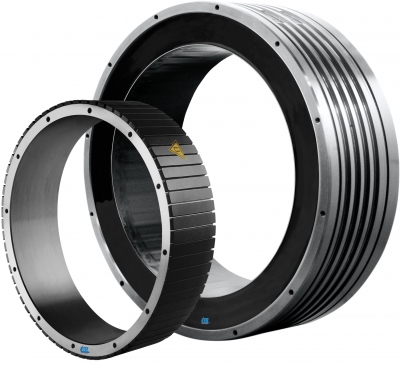

ETEL introduced the newest advancement of its torque motor family, the TMB+. In order to keep up with the high demands of the machine tool market, ETEL has taken its existing TMB line of torque motors and redefined it to increase its overall torque, size selection, and winding options to expand upon an already extensive and well renowned series of direct drive motors.

The TMB+ is fully pin-to-pin compatible with the TMB series but offers an increased performance of up to 22 percent continuous torque and up to 4 percent on top of it is already high peak torque. Also the TMB+ has reduced power losses, four different winding options per size and a new 200mm active length for each diameter, increasing its overall size selection from the TMB.

The TMB+ series comes in 62 standard model sizes with four different windings each, allowing the user to get maximum performance depending on how much torque, current, and speed needs is required. TMB+ motors can achieve a peak torque of up to 42,900 Nm and utilize flux weakening to increase it is speed capabilities. It also has the option of coming with ETEL’s IMTHP thermal module which, when coupled with ETEL’s torque motors, enables users to reduce their amount of safety margins while receiving precise and reliable temperature monitoring. ETEL torque motors are compatible with most CNCs.

The TMB+ series is designed specifically for direct drive applications and offers the following advantages over transmission-based devices:

- Fewer parts requiring lower overall costs

- Stable performance along the machine’s lifetime due to zero maintenance being required

- No backlash, allowing for better accuracy and repeatability

- Smooth, precise, and efficient motions

- Compact design

Contact Details

Related Glossary Terms

- backlash

backlash

Reaction in dynamic motion systems where potential energy that was created while the object was in motion is released when the object stops. Release of this potential energy or inertia causes the device to quickly snap backward relative to the last direction of motion. Backlash can cause a system’s final resting position to be different from what was intended and from where the control system intended to stop the device.