END USER: Ramona Enache, +31 634-824-992, www.tothepointer.com

SOLUTION PROVIDERS: DP Technology Corp., (800) 627-8479, www.espritcam.com; Logicad Solutions srl, www.logicad.ro

CHALLENGE: Design metal parts for a wine glass that sticks into the ground.

SOLUTION: CAM software that defines all the machining operations, cutting tools and machining parameters.

Designer Ramona Enache turned an idea into a commercial product with the help of ESPRIT CAM software from DP Technology Corp., Camarillo, Calif.

“It started while I was enjoying a glass of wine with friends in one of the beautiful parks of Amsterdam,” Enache said. “I dislike drinking wine from plastic cups, almost as much as I dislike drinking wine straight from the bottle.” For picnics and other outdoor excursions, she would often bring real wine glasses. “But after spilling the precious liquid several times in the grass, I realized I needed a glass that I could pin in the ground,” she continued. “The next day when I woke up, I still thought it was a good idea and I decided to make it.”

The Pointer glass sticks into the ground to avoid spilling its contents. Image courtesy Ramona Enache.

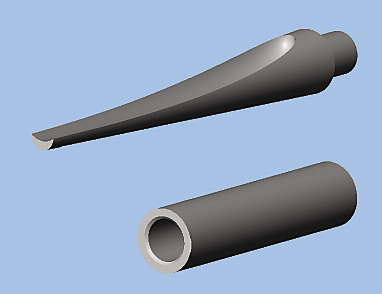

The stainless steel stem is comprised of two parts. Image courtesy Ramona Enache.

What Enache designed and made is the Pointer wine glass, which is basically a stylish wine glass with the glass stem replaced by a stainless steel pin. She produced about 200 prototypes by hand and received a positive response from friends and colleagues. As a result, Enache started a crowd-funding campaign on KickStarter to raise the money needed to go into production. She worked with Logicad Solutions srl, which represents ESPRIT in Romania, to create a detailed design and determine the best way to produce the metal parts.

That involved creating solid models and simulations to precisely define the geometry of her design concept and then 3D-print prototypes to evaluate their style, functionality and manufacturability, explained Dorin Dascalu, manager of Logicad. Dascalu and Enache concluded that the stainless steel stems should be CNC-machined from bar stock as two modular parts, and then be manually polished to impart a fine surface finish before assembly.

Both parts have nonuniform, contoured surfaces, thin walls and overhangs. “At first glance, these parts look like they would be easy to machine but, in reality, their sharp ends and the tough workpiece material make it quite difficult to avoid vibration, which would damage their appearance,” Dascalu said.

Enache and Dascalu evaluated several providers of machining services and selected S.C. Hermi Construct srl, a Romanian contract manufacturer. The company machines the metal parts on an Okuma Multus multitask machine in a single setup.

According to Dascalu, ESPRIT is “perfect” for defining the machining operations, cutting tools and machining parameters. In addition, the software offers a library of postprocessors certified by machine tool builders, and user feedback, observations and recommendations improve the post-processors.

Cristian Toader, a Logicad engineer, programmed the parts in less than 1 hour. He used the CAM software’s simulation system to view the machining operations and estimate the machining time and production costs. The first parts produced with the program met all dimensional requirements.

Today, Enache has customers in more than 20 countries and has received requests for customizing and producing accessories for the glasses, and the ones that involved metal parts were accommodated by Logicad programmers.

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.