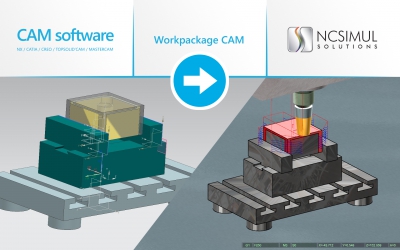

SPRING Technologies announces the launch of its CAM WorkPackages, a set of interfaces between commercially available CAM solutions and NCSIMUL 4CAM (formerly NCSIMUL CAM). WorkPackages are provided for for CATIA (Dassault Systèmes), NX (Siemens), CREO (PTC), TopSolid’Cam (MISSLER) and Mastercam (CNC Software Inc.). Ultimately, SPRING Technologies plans to offer its users direct interfaces with all the leading CAM products on the market.

NCSIMUL 4CAM is a powerful, innovative solution that is a vital add-on for a CAM deployment that makes production environments even more agile, according to the company. To do this it must enable users to transparently harness all their CAM project data, so that they can quickly and easily switch from one NC machine to another without writing new code. The CAM WorkPackages provide this capability.

More specifically, NCSIMUL 4CAM enables programmers in any sector of industry to directly and easily retrieve a part assembly, a clamping system and a rough stock model, with the machining and positioning coordinate system data, and associated cutting tool library, without having to go back into the toolpath program. In addition to the ISO files, the CAM WorkPackage gives users read access to the following APT files: CATIA, Esprit, GO2CAM, NX, Pro-E, Surfcam, to automatically identify and separate the different machining phases and facilitate the change to the new machine. This delivers further substantial time-savings when changing between NC machines, addressing production and machine availability imperatives.

This flexibility is primordial for factories that need to remain competitive today and going forward.

Customer benefits include:

- Optimized flexibility to adapt manufacturing to machine availability on the shop floor;

- Faster production rates and TRS from their NC machines;

- Safer machine changes in one-click, generating a new NC program that is simulated, checked, optimized and validated, whichever NC machine was used upstream or downstream in the process;

- Monitoring of all the modifications made following the change of machine in the different machining sequences;

- Capitalization on the work of the programmer by automatically reusing information from the CAM;

- Dynamic management and exporting of the intermediary rough stocks for instant data checks at all times during the machining phase.

Contact Details

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.