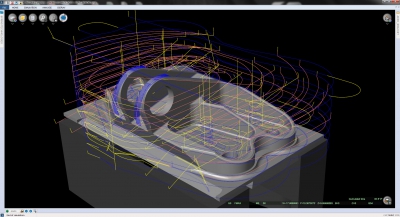

SPRING Technologies has enhanced the optimization capabilities of its flagship NCSIMUL package. The improvements are contained in the NCSIMUL OPTITOOL module of NCSIMUL MACHINE, SPRING Technologies’ CNC machine verification software for simulating, verifying, optimizing and reviewing machining programs.

The new capabilities include algorithms that transform working feed rates into rapid feed rates or specified maximum feed rates for approach and retract motions in both circular and linear toolpaths. The software’s Air Cutting Optimization mode can enable users to reduce machining times by 4 to 25 percent by minimizing air-cutting motions and optimizing entry and exit feed rates. This results in immediate and automatic savings on every part produced, even on existing programs.

Simple, one-click implementation requires no alteration to the toolpath or CAM system. The software is effective in FANUC, Heidenhain, Siemens and any other standard CNC languages. NCISMUL OPTITOOL also enables users to test different optimization strategies and provides graphic analysis comparing initial and optimized feed rates. Further, this optimization can be applied (repeated) on every machined part currently in process, multiplying the gains.

“Optimization of noncutting motions, as provided by these enhancements of NCISMUL OPTITOOL, represents a major opportunity for significant savings in machining time,” said Silvère Proisy, North American operations director for SPRING Technologies.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.