MecSoft Corp. has licensed MachineWorks’ cloud-computing technology. MachineWorks Ltd. is a provider of component software for CNC simulation, verification and polygon-mesh modeling. The new cloud-based technology provides CNC manufacturers with a solution for running simulation on a server whilst displaying the results on one or more remote clients.

Multiple MachineWorks simulations can be run concurrently on a single server and a single simulation can be synchronised across multiple clients simultaneously.

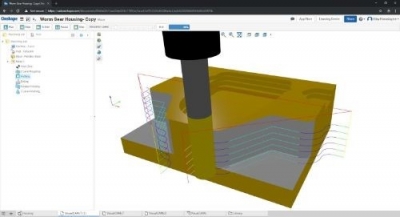

VisualCAMc for Onshape is MecSoft’s browser-based, first production level cloud CAM app for Onshape. Incorporating MachineWorks’ cloud-based libraries, VisualCAMc provides the functionality of MecSoft’s desktop-based VisualCAM running on the cloud on any internet-connected device that supports standard web browsers.

Cloud-computing is radically changing the way industries work and communicate. Manufacturing software providers seeking to provide their users with the many advantages of cloud-based working can now benefit from MachineWorks’ client-server APIs.

“We chose simulation libraries from MachineWorks for our cloud CAM product VisualCAMc because of the unparalleled quality and speed of their libraries, ease of integration and also their excellent support. These factors combined with our long and valued relationship with MachineWorks made it a natural choice for us. We are very happy with the results and are excited to be one of the first companies to implement production level CAM on the cloud,” says Joe Anand, president and CEO of MecSoft Corp.

“We are delighted that MecSoft have chosen MachineWorks for their cloud-based product line. MecSoft has always been at the forefront of innovation. Their new VisualCAMc product brings serious CAM and CNC simulation to the cloud and provides opportunities for more efficient ways of working through continuous installation-free upgrades and real-time collaboration across geographically distributed sites,” says Richard Baxter, sales manager at MachineWorks.

MachineWorks offers a full cloud back-end combined with a flexible client supporting all common web browsers and cloud-enabled desktop applications via both C and JavaScript APIs.

Networked devices such as mobile phones, tablets, laptops and desktops can visualise and drive connected MachineWorks simulations running on a remote server. Multiple clients can access the same server simulation and a single server can support multiple simulations on multiple clients.

Geometry is native to the client allowing local graphical operations without server round tripping. As with the standard MachineWorks API, the client module allows applications to use MachineWorks graphics as provided or to combine MachineWorks geometry with their own graphics pipeline.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.