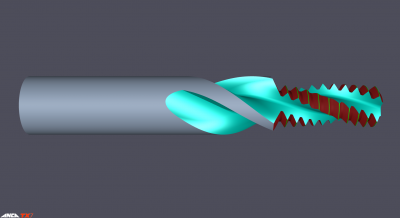

Thread milling is a versatile, cost-effective process for cutting a variety of threads, parts and workpiece materials on the same machine. This process produces an internal or an external thread by doing a helical interpolation on a CNC machine, which can make helical paths.

Thomson Mathew, ANCA product manager said: “Thread mills generate superior burr-free surface finishes and reduce tool inventory costs. Shops can use the same tool for both left and right-hand threads, as well as for different thread tolerances. A broad range of materials and hole diameters can also be thread milled with the same tool. Unlike tapping, threads produced through milling can be machined to full depth at high accuracy, even in hardened materials. Some of the other advantages are faster cycle times and less tool breakage – basically these are a really effective tool.”

Advantages of the Threadmill

- Provides a 20 to 40 percent increase in tool life compared to other threading process.

- Increased strength and rigidity specially on hard material when cutting forces are applied.

- Reduces inventory costs of tooling.

- Threadmill Inserts allow for small to larger cutter diameters.

Thomson continued: “Our tool and cutter grinders can effectively manufacture a range of thread milling cutters. Customers wanting to manufacture this cutters in large volume or for lights out manufacturing can make use of the Blum laser for measurement and compensation inside the machine.

“There are so many great applications available that people are not familiar with. For example – 'thrilling.' This is the process of threading and drilling (accomplished in the reverse order). The cutting tool tip is shaped like a drill while the body has a thread-shaped form with a countersink cutter form near the shank. The cutter first plunges to drill the hole and then the thread is circularly interpolated while the chamfer is also formed. The advantage is this process eliminates a tool, toolholder and tool change.”

The Blum laser inside the machine can measure and compensate the tool diameter and crest width. There is an option in software to control the upper and lower tolerance for the diameter compensation.

The software has two different operations for thread grinding and cresting. This allows you to choose roughing and finishing wheels for threading and to use number of passes if required. The laser measurement is done after the cresting for diameter and width compensation.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- countersink

countersink

Tool that cuts a sloped depression at the top of a hole to permit a screw head or other object to rest flush with the surface of the workpiece.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- interpolation

interpolation

Process of generating a sufficient number of positioning commands for the servomotors driving the machine tool so the path of the tool closely approximates the ideal path. See CNC, computer numerical control; NC, numerical control.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.