Cylindrical die thread rolling is a cool method for taking the heat off manufacturing thin, deep helical fins on long lengths of thin-walled tubing. The process is suitable for making a variety of everyday products, achieving fast, economical production when metalcutting machining just doesn’t cut it. One such product is finned tubing for heat exchangers.

Improving the energy transfer efficiency of cooling and heating fluids has been a challenge since the Industrial Revolution. Any device performing work requires a transfer of energy to make the work happen. A portion of the energy goes into the work, and another portion comes out as heat due to efficiency losses in the system. Methods that improve the energy transfer efficiency of the original device or that capture the heat loss for reuse are in constant demand. It all comes down to heat transfer.

Heat transfer can be accomplished by a heat exchanger, which transfers energy from one fluid to another liquid or a gas. One of the simplest methods of heat exchange without mixing fluids is the use of a tube through which one fluid is passed at one temperature while another fluid is passed around the outside at another temperature. Heat is transferred from the hotter fluid to the cooler one through the tube wall. To increase heat exchange efficiency, such a tube is manufactured with fins that protrude radially outward from the tube surface, thus creating a fin tube. Finned tubing can be found at the core of most heat exchanger devices.

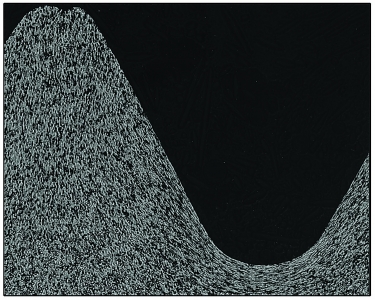

A fin tube cross section with internal profiling. Image courtesy of Kinefac

Why a Fin Tube?

The simple answer is that the efficiency or rate of heat transfer is affected significantly by the surface area of exposure. Fluids have a heat transfer coefficient, which is the amount of heat per unit area they can transfer. By increasing the usable area, multiplying the heat transfer coefficient by that increased area results in more capacity for heat transfer. The outside surface area of a plain tube easily can be increased five to 20 times by adding fins to the outside surface.

A fin tube also can have a finlike profile on the inside surface to increase the surface area and promote directional fluid flow or mixing. Turbulence induces mixing of each fluid, which can improve heat transfer for individual fluids. Turbulence can be controlled by the geometry and arrangement of the fins on the inside or outside of the tube. A helical fin path is most common on either or both surfaces.

Before talking about manufacturing finned tubing, let’s look at the characteristics of a typical fin tube product. Fin tubes come in all shapes, sizes and materials with varied fin heights and thicknesses. The tubes generally are made of welded tubing in stainless and low-carbon steels, copper, brass, aluminum and exotic alloys. One important characteristic to consider for manufacturing is length. Some fin tubes are manufactured in continuous lengths of 100' or more, which then are bent into compact shapes to fit inside various heat exchangers. Other relevant traits are tube diameter and wall thickness, fin height, the number of fins per inch and tube material grade and construction.

In simple terms, a fin tube can be thought of as a hollow, threaded rod. However, the simplicity starts to diminish when there are 60 or more thin threads per inch with an additional threaded profile on the ID over a 100' length. Two processes traditionally are employed to produce external threads on the outside of a workpiece: thread cutting and thread rolling. Both methods have strengths and weaknesses. Thread rolling is the process to beat, though, when it comes to manufacturing fin tubes at high rates of speed. There are also benefits with material savings, strength, surface quality and the ability to generate internal profiles without wasting material by generating chips.

A cross section of rolled thread grain flow. Image courtesy of Kinefac

When cutting an external thread on a lathe, a single-point cutting tool plunges radially into one side of the workpiece and traverses along its exposed length. Multiple passes at successively deeper depths usually are required to achieve the full thread form. It can take minutes to accomplish this task on a length less than 10" or 12". Single-point thread cutting creates a force imbalance on one side of the workpiece due to the forces generated by the cutting tool.

Deflection of the workpiece is always a consideration. The workpiece geometry and cutting forces dictate the limits of exposed length that can be threaded, above which deflection and stability problems will occur. Once the limit is exceeded, rolling is the best option.

Rolling Basics

When rolling an external thread of discrete length, two or three rotating cylindrical dies plunge radially into the workpiece to some depth while rotating it to replicate their geometric surface features into the periphery of the workpiece surface. This is referred to as infeed rolling. For longer continuous lengths of a threaded product, the through-feed rolling process is used by skewing the axes of the rolling dies at an angle to generate through-feeding action of the workpiece.

In either case, the blank material is forced to conform to the die geometry without removing or gaining material. Therefore, thread rolling is a constant-volume process. The starting pre-roll blank is smaller in diameter than the final thread major diameter—usually somewhere near the thread pitch diameter—because material from the blank is displaced radially outward by the dies to fill the form. Material also can and will flow in two other principal directions, axial and circumferential, depending on several factors, such as the degree of form fullness or the ratio of thread depth to root diameter.

A typical machine screw thread can be rolled into a bolt blank in a few seconds. The feeding of the bolt blank into and out of the rolling machine usually takes longer than the rolling process itself. Rolling generates an uninterrupted grain flow around the rolled root, which helps enhance strength to a rolled thread over a cut thread. Other characteristics, such as material workhardening and a highly burnished surface from the rolling action, also help increase the strength and quality of a rolled thread.

The aforementioned advantages make the rolling process suitable for mass production of a long, continuous fin tube product that has good strength characteristics and process stability. Hollow components have relatively thin walls, which require a form to be rolled on them, and are processed using three-cylindrical die rolling. The three dies simultaneously converge on the workpiece, trapping it on a constant centerline while substantially preventing deformation of the tube with balanced forces at each die contact. An internal supporting mandrel sometimes is positioned inside the tube under the deformation zone to provide additional stability.

Kinefac’s MC-6 FT/I high-precision fin tube rolling machine. Image courtesy of Kinefac

As an added benefit of the rolling process, the internal mandrel can be made with a helical profile on its surface to replicate a helical form on the inside diameter of the tube, the benefits of which were described earlier. This operation would be impossible for long lengths of tubing using a cutting tool on the end of a boring bar.

Compared with cutting, the three-die through-feed rolling process can roll continuous lengths of form at high speed. Thin-wall rolling applications are also more susceptible to increased axial material flow. With fin tube rolling, depending on the depth of form and change in the cross section area in the rolling deformation zone, there can be significant axial stretching of the tubing on the order of 10% to 20%. That is 10% to 20% less blank tubing length required as raw material input.

Speed and Flexibility

It is not uncommon for fin tubes with low fin heights and 15 to 20 fins per inch to be rolled in upward of 10' or more per minute using straight annular disc dies. That’s 2 in./sec. of a finish-rolled product. Production rates depend on the number of fins per inch, the number of helical start paths on the tube, die speed, die skew angle, tube diameter and die diameter. When using straight annular discs, the disc die skew angle is matched to the part lead angle. As the number of helical start paths on the tube increases, the die skew angle must increase to match the higher lead angle. A higher skew angle means faster feed rates at a given disc rpm.

As previously noted, long lengths of fin tubes typically are bent into special shapes to fit inside a heat exchanger shell. It is desirable to have no fins present where bends occur when performing a bending operation. This avoids fin damage and takes advantage of the full tube cross section. Fin rolling machines can provide radial motion of the disc dies both into and out of the tube to allow spacing between finned sections as required. The tube advances axially through the dies during the period of die retraction to create a length of space before plunging the dies back into the tube to continue producing rolled fin.

A typical shell and tube heat exchanger. Image courtesy of Thermal Transfer Systems Inc.

It is critical that all the fin rolling dies simultaneously contact the workpiece to maintain a constant rolling centerline and full stability during rolling. It is also critical to sustain constant radial position of the penetrated dies into the tube throughout the rolling process to maintain dimensional stability of the rolled tube root diameter and fin height.

For shops with high-volume production or that struggle to cut continuous lengths of finned tubing or other helical and annular threadlike forms, consider cylindrical die through-feed rolling. Production speed, material savings, strength, quality and performance can justify the capital expense.

For more information about thread rolling, view a video presentation at www.ctemag.com by scanning the QR code on your smartphone or entering this URL on your web browser: cteplus.delivr.com/24y3t

A Brief History of Thread Rolling

Roll forming has existed since ancient times and can be traced back to when potters pressed and rolled a piece of clay between their hands to roll it into a new size. The first partially mechanized, hand-operated roll-forming devices for working metal appeared in the 1600s and pressed ridges into the sides of coins to deter thieves from scraping away shavings of the precious metals.

In the mid-1800s, the first fully mechanized flat die and cylindrical die thread-rolling machines were developed for rolling low-precision wood screw threads and higher-precision machined metal screw threads. Demand for higher-quality machined screw threads in the aircraft and automotive industries around the time of World War II pushed rolling machine builders to achieve a new level of quality for mass production of high-precision screw threads.

Today, the rolling process often is used as a secondary or final manufacturing operation to produce high-precision threads and other helical and annular forms in exotic alloys on critical components, such as aircraft landing gear.

—David C. Willens

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- boring bar

boring bar

Essentially a cantilever beam that holds one or more cutting tools in position during a boring operation. Can be held stationary and moved axially while the workpiece revolves around it, or revolved and moved axially while the workpiece is held stationary, or a combination of these actions. Installed on milling, drilling and boring machines, as well as lathes and machining centers.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

- lead angle

lead angle

Angle between the side-cutting edge and the projected side of the tool shank or holder, which leads the cutting tool into the workpiece.

- low-carbon steels

low-carbon steels

Group of carbon steels designated by American Iron and Steel Institute numerical classification as AISI 1005, 1006, 1008, etc., up to AISI 1026, for a total of 16 grades. They are softer and more ductile than other carbon steels. Composition of low-carbon steels is 0.06 to 0.28 percent carbon, 0.25 to 1.00 percent manganese, 0.040 percent (maximum) phosphorus and 0.050 percent (maximum) sulfur. See high-carbon steels; medium-carbon steels.

- mandrel

mandrel

Workholder for turning that fits inside hollow workpieces. Types available include expanding, pin and threaded.

- metalcutting ( material cutting)

metalcutting ( material cutting)

Any machining process used to part metal or other material or give a workpiece a new configuration. Conventionally applies to machining operations in which a cutting tool mechanically removes material in the form of chips; applies to any process in which metal or material is removed to create new shapes. See metalforming.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- profiling

profiling

Machining vertical edges of workpieces having irregular contours; normally performed with an endmill in a vertical spindle on a milling machine or with a profiler, following a pattern. See mill, milling machine.

- thread rolling

thread rolling

Chipless, cold-forming material-displacement process where a rolling head is pressed into the workpiece to create threads. The material is stressed beyond its yield point, which causes it to be deformed platically and permanently. There are three basic types of rolling heads: axial, radial and tangential.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.

- workhardening

workhardening

Tendency of all metals to become harder when they are machined or subjected to other stresses and strains. This trait is particularly pronounced in soft, low-carbon steel or alloys containing nickel and manganese—nonmagnetic stainless steel, high-manganese steel and the superalloys Inconel and Monel.