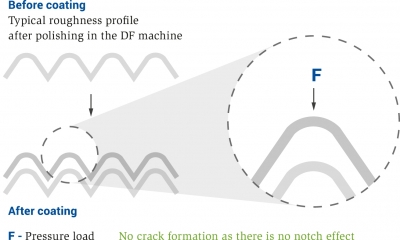

Otec machines allow the quality of carbide tools to be improved considerably. The special procedure enables the chip grooves of carbide cutters and drill bits, for example, to be polished to a high gloss.

Generally, the chip flow is dependent on surface smoothness. When the chips are able to flow better, there is less tailback on the cutting edge. This significantly reduces the pressure on the cutting edge. As the chips are removed from the chip groove more quickly, the chips are heated less.

These positive effects of the smooth surface mean that higher cutting speeds and significantly longer tool life can be achieved. The smooth surface also reduces the risk of fusing with the material being machined. The polish enables higher cutting values and feed rates to be achieved.

Contact Details

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.