Following its tradition still today, Lach Diamond Inc. offers service for setting single-point dressing diamonds and regrinding of profile diamonds. “We owe this to our customers,” emphasize the managing directors who are looking back to an almost 100-year anniversary; while they also reaffirm that “purchasing diamonds is a matter of trust.”

The traditional product range for the dressing of grinding wheels includes not only single-point dressers (e. g. the Diaform chisel) but also sintered multiple-point diamond dressers and aggregates.

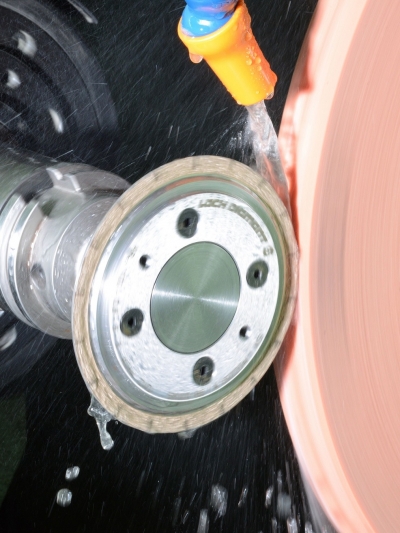

By now, the special “future for today – tools” product segment features the internationally well established »Dia-Fliese-perfect« on the top of the list, closely followed by »drebojet-plus« (pictured), the alternative diamond dressing roll system for the CNC dressing and profiling of conventional and CBN grinding wheels.

The product line for dressing and profiling grinding wheels is completed by the »rotary-dress« diamond dressing rolls, negatively manufactured. In this context, Lach Diamond refers to the success and technical know-how of Lach-Form GmbH & Co. Diamond Engineering KG, founded in the mid 1980s.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- dressing

dressing

Removal of undesirable materials from “loaded” grinding wheels using a single- or multi-point diamond or other tool. The process also exposes unused, sharp abrasive points. See loading; truing.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- profiling

profiling

Machining vertical edges of workpieces having irregular contours; normally performed with an endmill in a vertical spindle on a milling machine or with a profiler, following a pattern. See mill, milling machine.