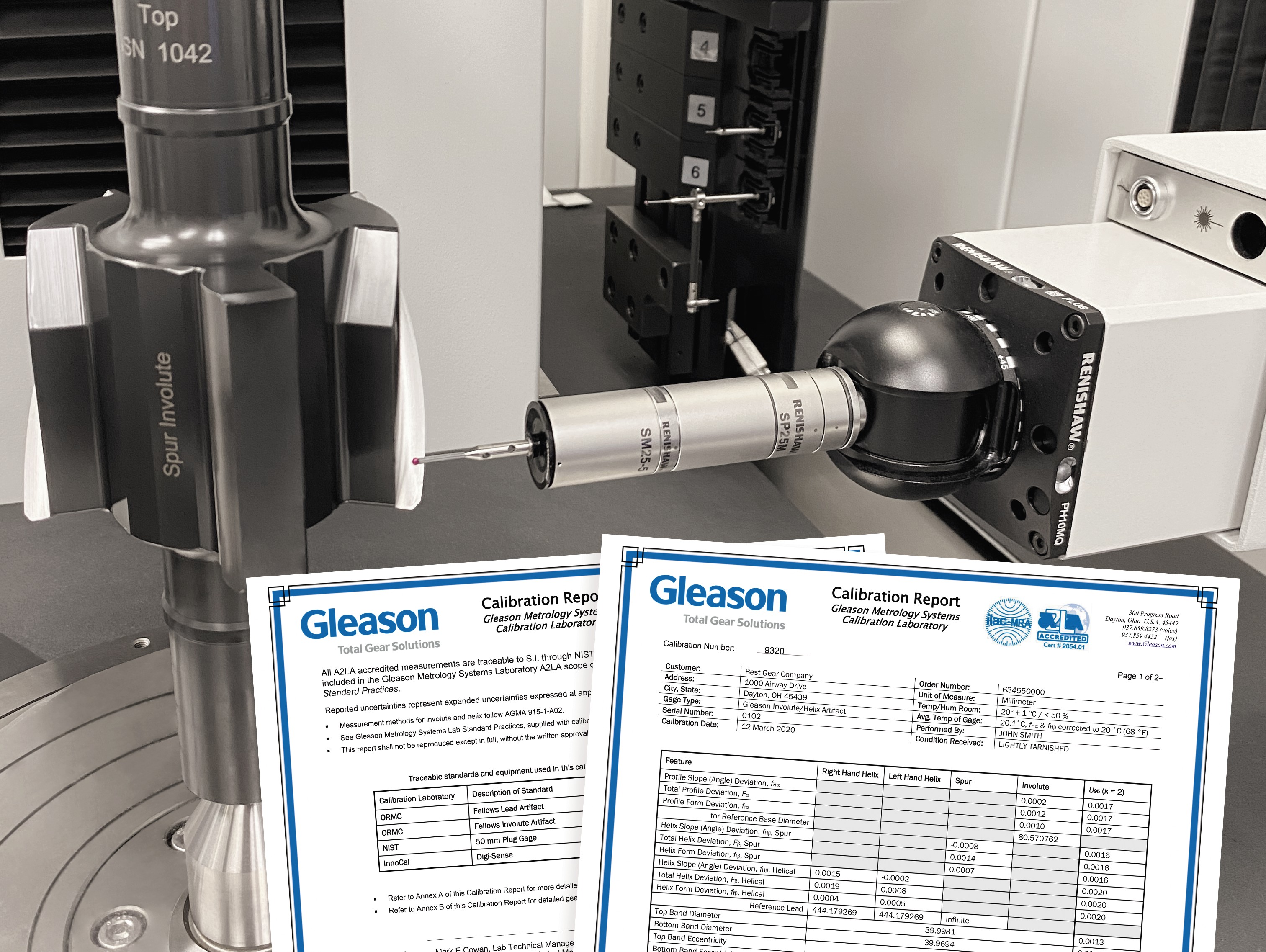

Rochester, New York (USA). Gleason Metrology Systems’ Gear Calibration Lab now features an enhanced quality system and ISO/IEC 17025:2017 accreditation, lower measure measurement uncertainties, and more comprehensive A2LA accredited calibration services with the addition of the latest Gleason 300GMSL Gear Measuring System and GAMA 3.2 analytics software.

The 300GMSL gear measurement system, utilizing our proven accuracy enhancement technologies to provide the highest degree of accurate gear and spline calibration, is now commissioned to provided accredited calibration of new parameters and ranges including diameters of plain cylinders and rings, dimension over/under balls, and tooth thickness, on gears and splines diameters up to 300 mm.

Additionally, the lab provides length measuring capabilities, reduced length measurement uncertainties for diameter, dimension over/under pins as well as calibrate sphere roundness for precision spheres including diameter and roundness up to 25 mm diameter spheres.

With the addition of these new services, expedited calibrations can now be provided in less than seven days on request. Services include the supply of new master storage cases and a wealth of non-accredited contract services for gears, splines, and spiral bevels up to 400 mm diameter.

Gleason Metrology Systems can also provide A2LA Accredited on-site calibration of analytical gear and spline measurements regarding gear involute and helix.

Gleason Metrology Systems A2LA Accredited Calibration Laboratory Complete list of Scope of Accreditation

A2LA accredited field calibration of analytical gear and spline measurement (involute, helix)

Outside diameter: plain cylinders and gear/spline, up to 300 mm diameter

Inside diameter: plain rings and gear/spline, 20 to 300 mm diameter

Precision sphere diameter and roundness, 0.5 to 25 mm sphere diameter

Dimension over pins/balls, up to 300 mm diameter

Dimension between pins/balls, 20 to 300 mm

Tooth thickness of external/internal involute gear/spline, up to 10 mm tooth size

Involute curve of external/internal gear/spline, 5 to 356 mm

Helix of external/internal gear/spline, 0 to 42 deg and 5 to 250 mm

Eccentricity/concentricity of slow taper and LeCount Arbors, up to 125mm

Pitchline runout, reference artifact, gear, or spline, up to 250 mm

Single pitch, reference artifact, gear, or spline, up to 250 mm

Cumulative pitch (index), reference artifact, gear, or spline, up to 250 mm

Contact Details

Related Glossary Terms

- calibration

calibration

Checking measuring instruments and devices against a master set to ensure that, over time, they have remained dimensionally stable and nominally accurate.

- metrology

metrology

Science of measurement; the principles on which precision machining, quality control and inspection are based. See precision machining, measurement.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.