325linear Grinding Machine

325linear grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">Grinding Machine

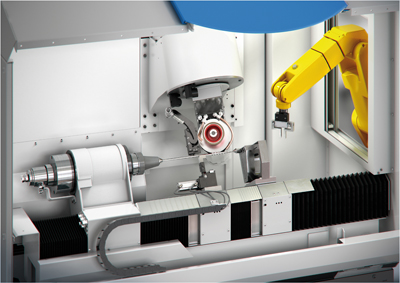

Schütte announces the introduction of its new 325<em>linear </em>machine, a 5-axis CNC grinder with extended X- and Y-axis movement plus two auxiliary slides for workpiece clamping and improved grinding wheel guidance over the entire machining envelope.

Schütte announces the introduction of its new 325linear machine, a 5-axis CNC grinder with extended X- and Y-axis movement plus two auxiliary slides for workpiece clamping and improved grinding wheel guidance over the entire machining envelope. Microtools, gun drills, hob cutters and complex geometries can be accommodated on this new machine, which operates in the range of 2500-4000 rpm, typically. The additional second auxiliary slide enables the 325linear to utilize tool guidance, part support, tailstock or workpiece pallets in operation. This new Schütte machine further expands the user's automation possibilities, as it also offers significant advancements in wheel change and robotic workpiece handling.

Specifically, on the a-axis, a user can install collet chucks, hydraulic expansion chucks or multi-range chucks. With the automated collet changer on the machine, workpieces with different diameters can be clamped with high concentricity in the unmanned loader station. The Schütte a-axis configuration on this machine also permits position-oriented clamping of non-rotationally symmetrical workpieces. In this way, sequential workpieces with various roughing and finishing requirements can be preset on the machine for continuous processing.

Likewise, this new Schütte grinding system offers scalable automation, with a 140-position tool changer, 5-24 grinding wheel magazine and a flexible robotic tool gripper for changing the smallest micro tools as available options. The same base machine can be utilized for continuous production of a single part in a work cell setup or used for sequential one-off work, as needed.

The 325linear features a universal rotation a-axis with a high level of concentricity (<0.0001º resolution) and pitch accuracy, while the X-, Y- and Z-axis resolution is maintained at <0.1µm. The swiveling c-axis for the grinding head has a 225º range of motion, also with <0.0001º resolution accuracy. The primary motor spindle operates up to 12,000 rpm with 15kW max. drive output, while the grinding spindle option affords a max. speed of 24,000 rpm. Linear axis travel on the machine is (xyz) 480mm x 250mm x 275mm.

The machine is offered with the proprietary SIGSpro (Schütte Integrated Grinding Software) as the programming interface, allowing users to assign clamping options for each grinding operation being performed. When the support and tool guidance system are used, preset distances from the grinding wheel to the workpiece can be defined and held constant. In the 3D mode, all cycle steps can be simulated, controlled and optimized for exact estimating, collision avoidance and even external workstation integration with the other workpieces.

All motion control on this new grinder is maintained on a Siemens 840D sl CNC with compatible drive technology.