Contact Details

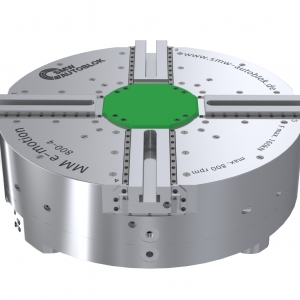

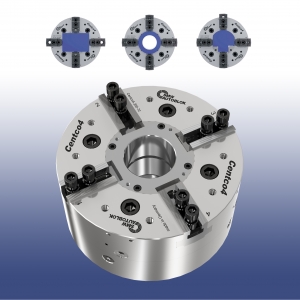

SMW Autoblok, a world leader in the design and manufacture of rotational chucks, stationary workholding, tooling and custom engineered solutions for the machine tool industry, presents the BB-FZA2G pneumatic 3+3 sequencing air chuck featuring an extended stroke clamping range and three self-centering jaws with axial adjustment.

Ideal to handle the harsh demands of the Oil and Gas industry, BB-FZA2G allows for quick and easy setup of odd shaped pipe for threading and re-threading. Thanks to incorporating three jaws with axial adjustment of the centering position while also using three compensating jaws with extra long rapid and clamping stroke of 1.5”, there is no need to re-shim the part. This enhances operator safety and greatly increases overall productivity.

Ideal for machining straight and bent pipe, BB-FZAG is available in 740, 800, and 920 mm to cover an extensive range of pipe diameter sizes, and features a large through hole of 275, 330, and 390 mm. This state-of-the-art sequence chuck with pressure control safety system greatly increases production output without re-shimmming of jaws.

Related Glossary Terms

- centering

centering

1. Process of locating the center of a workpiece to be mounted on centers. 2. Process of mounting the workpiece concentric to the machine spindle. See centers.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

PRODUCTS

PRODUCTS