Contact Details

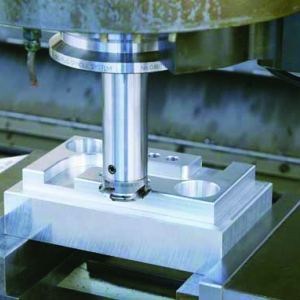

BIG KAISER introduces the 4mm mini indexable boring bar – suitable for small component machining. To date, BIG KAISER has one of the smallest indexable inserts in the market.

The mini indexable boring bar helps meet the increasing demand for successfully boring small parts in industries like medical and aerospace, such as machined medical implant devices and micro-sized components.

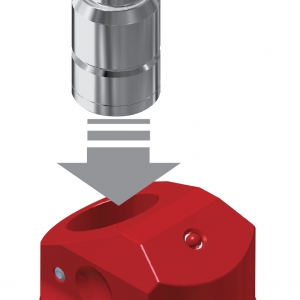

The main advantage of this product is the cost savings of replacing just the indexable insert in production versus replacing the entire bar where the cutting edge is integral to the bar. The inserts can be easily exchanged without disturbing the overall geometry of the tool, providing optimized cutting results.

Indexable inserts feature sharp cutting edges that help lower cutting forces and vibration and inserts with special developed cutting geometry for carbon steel, alloy steel and aluminum are available.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- boring bar

boring bar

Essentially a cantilever beam that holds one or more cutting tools in position during a boring operation. Can be held stationary and moved axially while the workpiece revolves around it, or revolved and moved axially while the workpiece is held stationary, or a combination of these actions. Installed on milling, drilling and boring machines, as well as lathes and machining centers.

- indexable insert

indexable insert

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

PRODUCTS

PRODUCTS