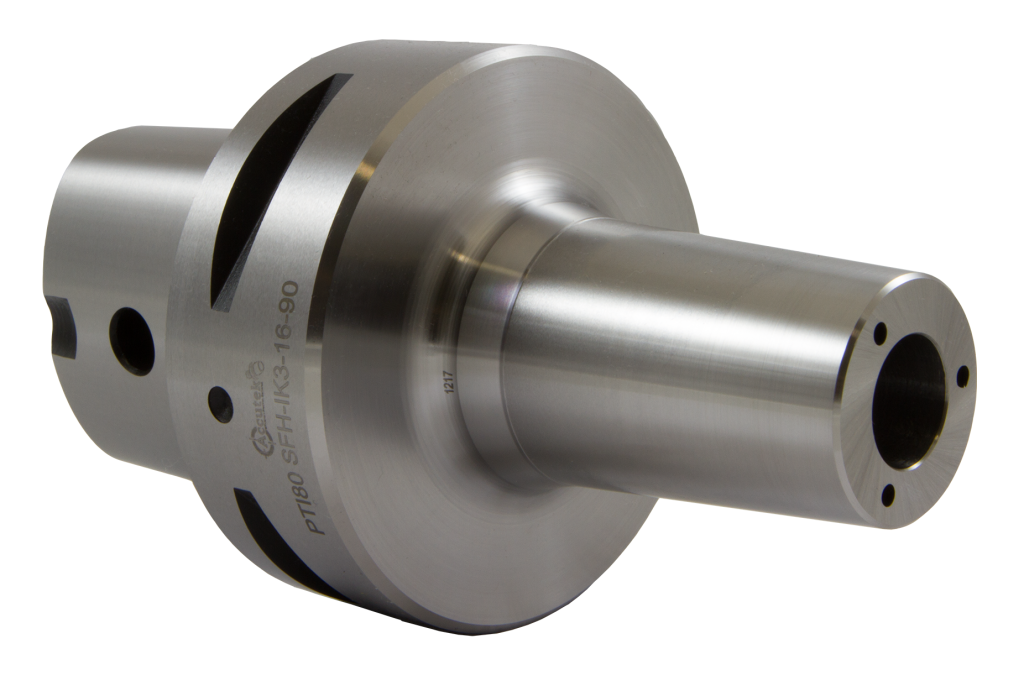

AccuKool Coolant Port Holes

AccuKool Coolant Port Holes

Specially designed coolant holes that are central to the body diameter and ID diameter to maintain the thickest and strongest body design for superior grip strength with coolant flow directly targeted at the "vortex" intersection for maximum coolant follow to and through the cutting flutes.

Accutek Inc. is expanding their AccuGrip Shrink Fit tool holder product offering with the new AccuKool coolant port holes through the body of the shrink fit holder. Specially designed coolant holes that are central to the body diameter and ID diameter to maintain the thickest and strongest body design for superior grip strength with coolant flow directly targeted at the "vortex" intersection for maximum coolant follow to and through the cutting flutes. Their hole size, design, and angle are critical to the exact placement of coolant into the centrifugal "vortex" created by rotational RPM of cutting tool to minimize the negative impact of centrifugal air flow created by the spinning tool. Improved coolant flow improves tool life, part finish, and overall productivity.