Contact Details

Tungaloy has added AH3225 grade inserts to its DoTriple-Mill and DoQuad-Mill face milling cutters for enhanced steel machining performance.

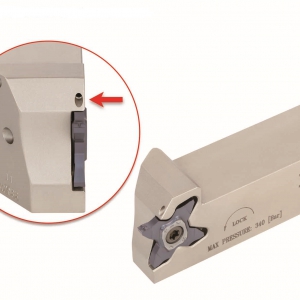

All-round face milling cutter, DoTriple-Mill can use round, square, and octagonal inserts in the same pockets, which are available in pressed-to-precision M-class inserts, ground-to-precision G-class inserts, and wiper inserts for extra surface precision.

DoQuad-Mill offers 88 degree entry angle, allowing this face milling cutter to cut extremely close to the walls and fixtures without interference. Its double-sided inserts with eight cutting edges feature a large rake angle that helps lighten cutting forces. This allows the face milling cutter to generate little to no chatter even with a perpendicular entry angle of 88 degrees.

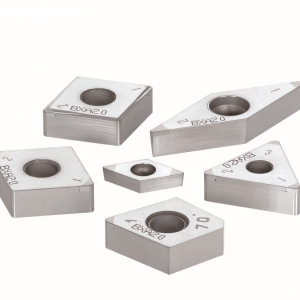

These two cutters now offer AH3225 grade inserts with Tungaloy’s latest coating technology. The nano-multilayer structure, strong coating-substrate adherence, and super-hard coating surface, engineered, the coating provide the grade with superior wear and fracture resistance. Combined with dedicated tough carbide substrate with superior thermal shock resistance, AH3225 prevents thermal cracks on the cutting edge from developing to catastrophic failure, while ensuring reliability and exceptionally long tool life in all steel machining operations.

Related Glossary Terms

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS