Contact Details

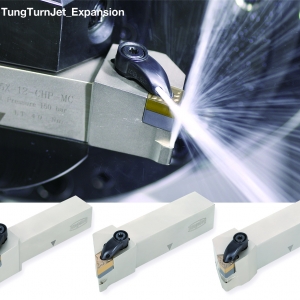

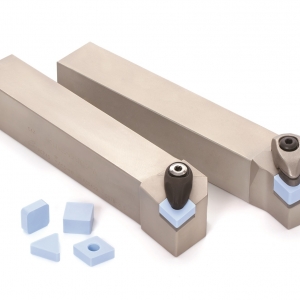

Tungaloy has announced a significant expansion of TungCut inserts with 87 total additional inserts in the latest PVD grades AH6235 and AH8005.

TungCut is an extremely flexible grooving tool system offering a large variety of chipbreakers and toolholders that range from standard mono blocks to modular blades with through coolant capabilities. Unique and strong insert clamping system provides the tool with process security and long tool life.

AH6235 is the latest titanium-enriched nano-multilayered PVD coating with extremely hard microstructure. Combined with a dedicated tough carbide substrate, the grade provides the insert with exceptional reliability during parting and grooving operations with interruptions. AH8005 is another PVD grade incorporating high aluminum-content multilayered coating with high hardness. The grade integrates a dedicated carbide substrate with well balanced hardness and fracture toughness, demonstrating superior wear resistance during high speed machining.

Together with successful AH7025 grade for first choice, AH6235 and AH8005 grades will enhance TungCut performances in parting and grooving operations with interruptions, as well as grooving and turning operations with aggressive conditions.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- fracture toughness

fracture toughness

Critical value (KIC) of stress intensity. A material property.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- microstructure

microstructure

Structure of a metal as revealed by microscopic examination of the etched surface of a polished specimen.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS