Contact Details

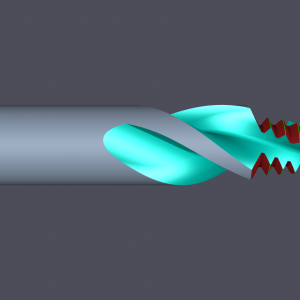

Solid endmill and drill production is a highly competitive market, making it challenging to differentiate yourself from your competitors. Inserts for milling and drilling applications offer various advantages over solid carbide tools, but present unique challenges in manufacturing. For those that successfully master the production of insert tools, new market opportunities can be yours. ANCA’s insert grinding solutions may just be the answer you need to take this step.

Inserts appeal to users of tools, firstly because one tool body can take a variety of inserts, making them very versatile. Additionally, the cost of replacing just the insert is significantly less than an entire solid carbide tool. For insert manufacturers however, the challenge is automated production of these uniquely shaped parts.

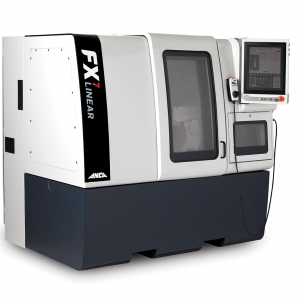

The ANCA Insert Solution, based on the MX tool grinding machine platform, offers work-holding, automation and supporting tool programming software to produce a diverse range of rotary endmill and drill inserts. Inserts that feature common locating datums and clamping features are an ideal fit for the ANCA Insert Solution.

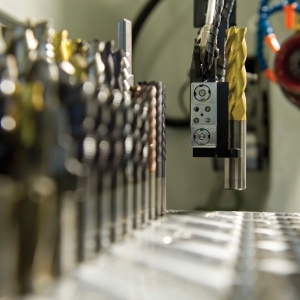

ANCA’s unique Insert Chuck provides the foundation of insert grinding capability. Its versatile design means one chuck can hold a variety of inserts with precise repeatability and necessary rigidity during the grinding operation. Onto the standard chuck, interchangeable jaws are fitted in minutes. These jaws are custom designed based on the insert datum and holding features, as well as considering wheel clearance for necessary grinding operations. ANCA will work with you to design jaw sets that cover your complete insert design and size range.

Economical production requires automation. For insert grinding, the RoboMate robot loading system is kitted up with the dedicated pallets and grippers for unattended manufacturing. As with the chuck jaws, ANCA will collaborate with you to design a range to pallets and grippers that suit your inserts.

Comprehensive and flexible programming software is the final element needed for insert grinding. As always, ANCA has it covered with iGrind – our industry-leading tool programming software, that caters for various special endmill and drill insert geometries. In addition, special digitizing routines will determine the datum location and exact position of the insert before commencing the grinding operation. This ensures the insert production batch remains accurate and consistent, delivering quality results expected in the market.

Finally, with production flexibility in mind, the insert grinding system can be easily switched over to solid carbide tool production, meaning a given grinding machine is not locked into production of just one tool type. By switching the Insert Chuck for PremierPlus collet system, and replacing RoboMate pallets and grippers, the transition to solid tool production can be done quickly and efficiently, ensuring your machines productive grinding time is maximized and adaptable to your market demands.

The insert grinding solution is offered not only on new machines, but can equally be retrofitted on existing MX machines. Setting up for diversifying your cutting tool product portfolio to include inserts has never been easier. Having alternate production capabilities that can quickly be adapted to meet customer demands is a winning long-term strategy for the success of your tool grinding business.

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding machine

grinding machine

Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpiece surfaces. When ultrasmooth surfaces and finishes on the order of microns are required, lapping and honing machines (precision grinders that run abrasives with extremely fine, uniform grits) are used. In its “finishing” role, the grinder is perhaps the most widely used machine tool. Various styles are available: bench and pedestal grinders for sharpening lathe bits and drills; surface grinders for producing square, parallel, smooth and accurate parts; cylindrical and centerless grinders; center-hole grinders; form grinders; facemill and endmill grinders; gear-cutting grinders; jig grinders; abrasive belt (backstand, swing-frame, belt-roll) grinders; tool and cutter grinders for sharpening and resharpening cutting tools; carbide grinders; hand-held die grinders; and abrasive cutoff saws.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

PRODUCTS

PRODUCTS