App Bundles for Machinists

App Bundles for Machinists

Indiana Technology and Manufacturing Companies (ITAMCO) has released three new bundled apps: CNC Machinist, Practical Machinist and Ultimate Machinist.

Indiana Technology and Manufacturing Companies (ITAMCO) has released three new bundled apps: CNC Machinist, Practical Machinist and Ultimate Machinist. These app bundles contain ITAMCO's most popular apps and are offered at reduced prices through the Apple App Store.

The CNC Machinist App Bundle has four apps that will help users build a CNC program and the settings to send to a CNC machine tool, including:

• Feed Rate Calculator calculates feed rate and speeds

• Grid Pattern Support gives X and Y positions for a grid pattern program

• Bolt Hole Circle Calculator calculates coordinates of a bolt hole circle based on the number of holes and X, Y coordinates

• iDNC, an iOS DNC settings app for CNC machine tool controls. DNC settings for multiple machine controls and types including, but not limited to, FANUC, Siemens, Mazak, Okuma, Haas. Also includes FTP (file transfer protocol) client server for part programs for CNC controls such as FANUC.

The price of the CNC Machinist App Bundle is $1.99. (Individual apps are $1.00 each.)

The four apps in Practical Machinist cover the basic tasks for the machinist, including:

• Feed Rate Calculator calculates feed rate and speeds

• Drill Tap calculates different size drills, taps, bolts, screws, and nuts

• Metal Weight Calculator calculates weights of different types of metals in various shapes

• Measure Threads measures threads with wire and calculates the best wire size

The price of the Practical Machinist App Bundle is $1.99. (Individual apps are $1.00 each.)

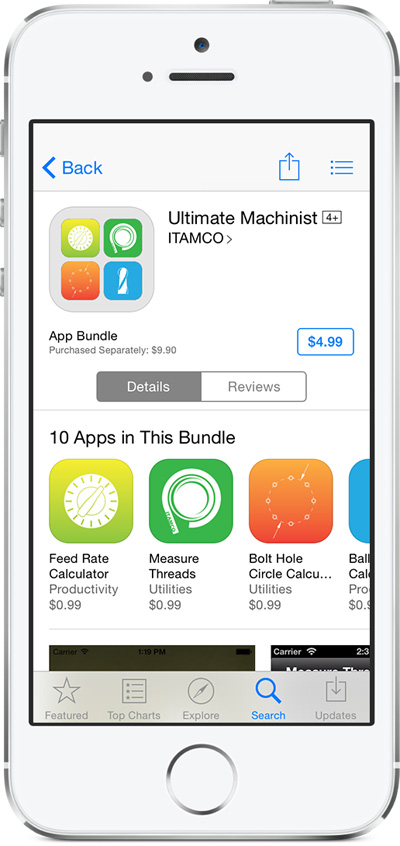

The Ultimate Machinist contains the 10 apps that every machinist needs, including:

• Feed Rate Calculator calculates feed rate and speeds

• Drill Tap calculates different size drills, taps, bolts, screws, and nuts

• Metal Weight Calculator calculates weights of different types of metals in various shapes

• Measure Threads measures threads with wire and calculates the best wire size

• Bolt Hole Circle Calculator calculates coordinates of a bolt hole circle based on the number of holes and X, Y coordinates

• Ball Nose Calculator calculates step-over and depth of cut for a ball nose end mill

• Sine Bar Calculator calculates the gage block stack, 1st angle, and/or 2nd angle given the sine bar size and one of the other variables

• Drill Point Calculator calculates drill point depth and countersink depth or angles

• Thermal Expansion Calculator calculates changes in dimensions or thermal expansion coefficient of a substance related to its thermodynamic property when heated, and expanding or contracting when cooled

• Surface Finish Calculator converts values between speed, corner radius, and surface finish value

The price of the Ultimate Machinist App Bundle is $4.99. (Individual apps are $1.00 each.)

The apps require iOS6.1 and can be purchased through the Apple App Store in iTunes. They are compatible with the iPhone, iPad and iPod Touch.