Contact Details

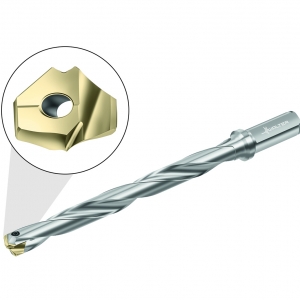

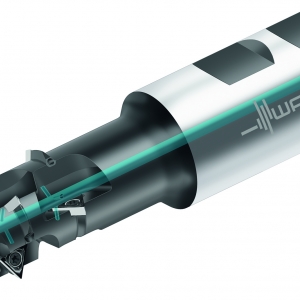

Blaxx F5055 slitting cutter from Walter USA LLC reportedly features robust and accurate construction with superior performance and process reliability that characterizes the Blaxx line. In addition, the superior concentric and axial run-out values of the F5055 cutter body keeps vibration to a minimum. The mill incorporates similar technology to the Walter Cut SX grooving system which is based on self-gripping, form-locking indexable inserts that provide ideal cutting force for the tool.

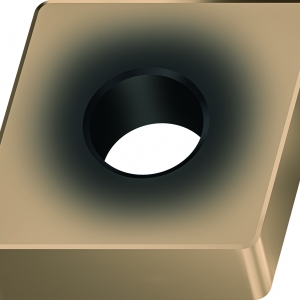

The productivity of the F5055 is further enhanced by Walter's Tiger-tec Silver cutting tool material. This advanced material is available in two grades, WSM33S and WSP43S, and in three insert geometries. The stable CE4 geometry is for medium to high feed rates and applications with good chip removal, the universal SF5 for most materials and low to medium feed rates, and the easy-cutting CF6 for good machining conditions and low feed rates or for non-ferrous metals. Walter supplies the F5055 in diameters of 63 to 250mm for insert widths of 2.0 to 4.0mm. Thanks to the universal performance of the cutting tool material, the F5055 is suitable for cast-iron, steel and stainless steel components.

Moreover, it can also handle materials with difficult cutting properties, making it suitable for the aerospace industry, where the production of large volumes of the highest quality components, typically made from difficult to cut material, demands tools with exceptional reliability.

Related Glossary Terms

- cutting force

cutting force

Engagement of a tool’s cutting edge with a workpiece generates a cutting force. Such a cutting force combines tangential, feed and radial forces, which can be measured by a dynamometer. Of the three cutting force components, tangential force is the greatest. Tangential force generates torque and accounts for more than 95 percent of the machining power. See dynamometer.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

PRODUCTS

PRODUCTS