Contact Details

BIG Kaiser Precision Tooling Inc. has been adding digital boring head options since 2010, beginning with the Series 112 for small diameter finish boring. Recent additions covering the middle range and large diameter range mean the company now offers a digital boring head to cover the full spectrum of finish boring sizes and series.

All of the new digital heads were designed geometrically similar to their analog predecessors, same range, roundness, shape and height, so you can swap an analog for a digital model without any reprogramming. Also, existing Kaiser accessories such as shanks, extensions, reductions, slides, boring bars and insert holders are compatible with the new digital tools.

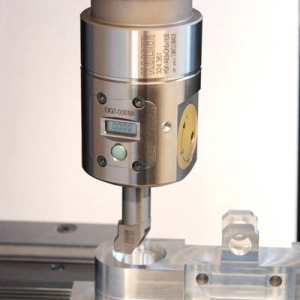

Additional features shared across the entire digital lineup include an IP 69K seal rating (highest possible) and a coated body to assure complete resistance to contamination and corrosion. For ease of use, a single button is all that is needed to operate the digital readout and the large, high-contrast display relates diameter corrections with a resolution of .00005"/diameter, or .001mm/diameter on metric heads. The tool carrier's measuring system shows the effective movement of the cutting edge and permits diameter corrections in both directions.

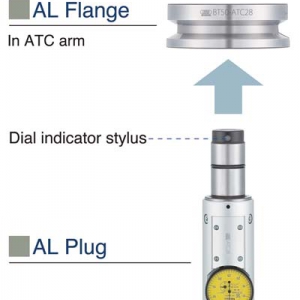

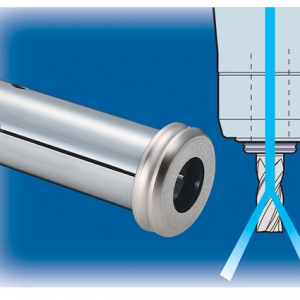

The new Kaiser Series 310 EWD Precision Finish Digital Boring Heads use existing insert holders from program 310 EWN to allow maximum boring range per head and compatibility with existing special design insert holders. Five heads cover the range of 1.614" to 8.000" in diameter, feature through-spindle coolant capability with directional coolant ports, and can perform back boring operations by simply reversing the insert holder.

The accuracy of a digital display is also now available on the Kaiser Series 318 Large Diameter Finish Boring System. The light-weight system is based on aluminum extension slides to support a variety of aluminum, and some steel, components. The series also features through-tool coolant supply to the cutting edge, for optimum chip making and breaking.

"These two new lines complement the Kaiser Series 112 EWD 2-54 line of digital precision boring heads for small diameters," says Jack Burley, BIG Kaiser vice president of sales and engineering. "Together, they cover the full range of finish boring needs."

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- boring head

boring head

Single- or multiple-point precision tool used to bring an existing hole within dimensional tolerance. The head attaches to a standard toolholder and a mechanism permits fine adjustments to be made to the head within a diameter range.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

PRODUCTS

PRODUCTS