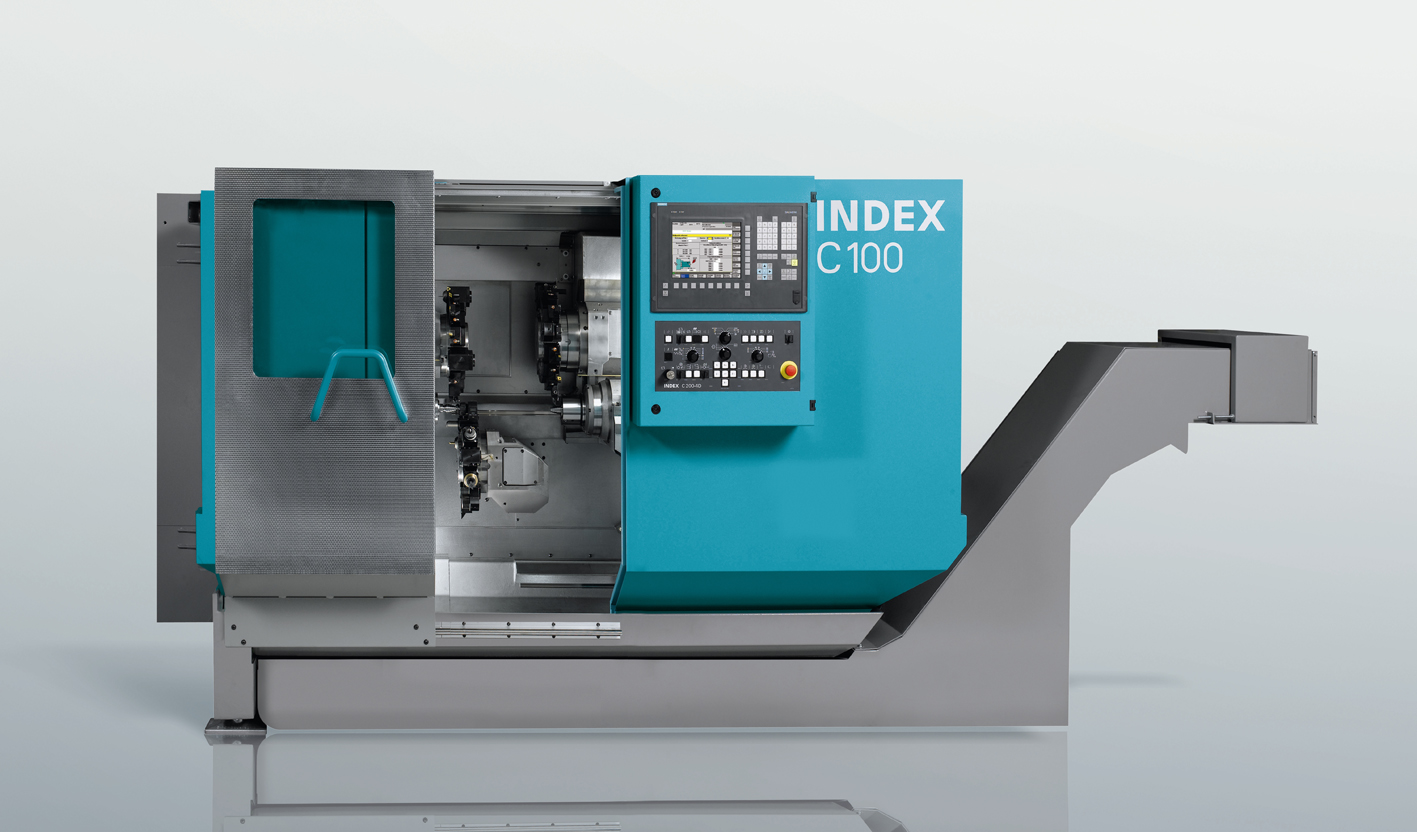

C100 Turn-Mill Machine

C100 Turn-Mill Machine

With three 14-position tool turrets and identical main and counterspindles, the new space-saving INDEX C100s are designed for fast, cost-competitive production of medium complexity parts turned parts from bar stock from 30mm to 42mm diameter. Ideal for small to medium lot sizes, the three-turret machines deliver high performance within a small floor space, and are targeted to handle fixed headstock work often run on Swiss-type machines.

With three 14-position tool turrets and identical main and counterspindles, the new space-saving INDEX C100s are designed for fast, cost-competitive production of medium complexity parts turned parts from bar stock from 30mm to 42mm diameter. Ideal for small to medium lot sizes, the three-turret machines deliver high performance within a small floor space, and are targeted to handle fixed headstock work often run on Swiss-type machines.

The INDEX C100 offers users a highly productive means of machining stock in the 30mm to 42mm range with more tools (42 quick-change tools, fixed and driven), higher horsepower, and greater torque but with the rpm typical of Swiss-style machines.

The C100 with 30-mm bar capacity comes with 9000-rpm spindles and 42mm bar capacity is available with 7000-RPM spindles. Both versions can run parts to 200mm in length. The C100 drives are powerful: 20/29 kW and 25/29 kW (100%/40%) for the 30mm and 42mm version, respectively. Motorized main and counter spindles are identical and liquid-cooled.

The machining flexibility of the C100 is a keynote of Index technology. Up to three tools can be at work simultaneously with both Y axes and backworking at the same time. And the counterspindle with linear-motor driven Z-axis can be synchronized with travel of turret 3. Counterspindle pick-up from the spindle is accomplished in just 1.5 seconds.

Because the C100 is configured to complete a wide range of parts from simple to complex, small to large batch sizes, users can expect extremely high machine utilization rates, which allow the C100 to be very cost-effective. Parts can be unloaded from the main or counterspindle.

Simultaneous machining with two Y axes at the main spindle or a Y-axis at the main spindle and also one at the counterspindle—each with 70mm travel—gives users the option to divide machining operations for optimal machining efficiency and flexibility. This freedom also is a key to reduced cycle times. For example, users can machine simultaneously with up to 3 tools driven tools for complete machining in a single setup, including heavy milling, and backworking with up to 5 tools.

The turret slides move in the X- and Z-axis directions on innovative single-plane guide ways. This permits rapids up to 60 m/min and accelerations up to 1 g with maximum rigidity. The plate-type guide way of the turret slides also means turrets glide directly on the machine bed, assuring high stiffness and dampening, resulting in longer tool life--up to 30 percent longer tool life and finer surface finish.

The open work area and vertical-bed machine design permits clear chip fall.

Each position on the 14-station turret is equipped for preset driven tools. Large tooling capacity means short setup times and very fast cycle times even for small batches. Tools are more easily accessible than on a Swiss machine and can be changed quickly. They lock with only one screw.

The CNC is easy to work with; plain text is used in display and operation and the screen shows all spindles and axes at one view. Superior programming with more than 70 user routines offers practical support down to the finest detail. Index programming contributes to optimal machine utilization and maximum productivity.

Assuring operator safety was a design consideration for the C100. Absolute measuring systems know axis and tool positions in every situation.