CAMWorks 2016

CAMWorks 2016

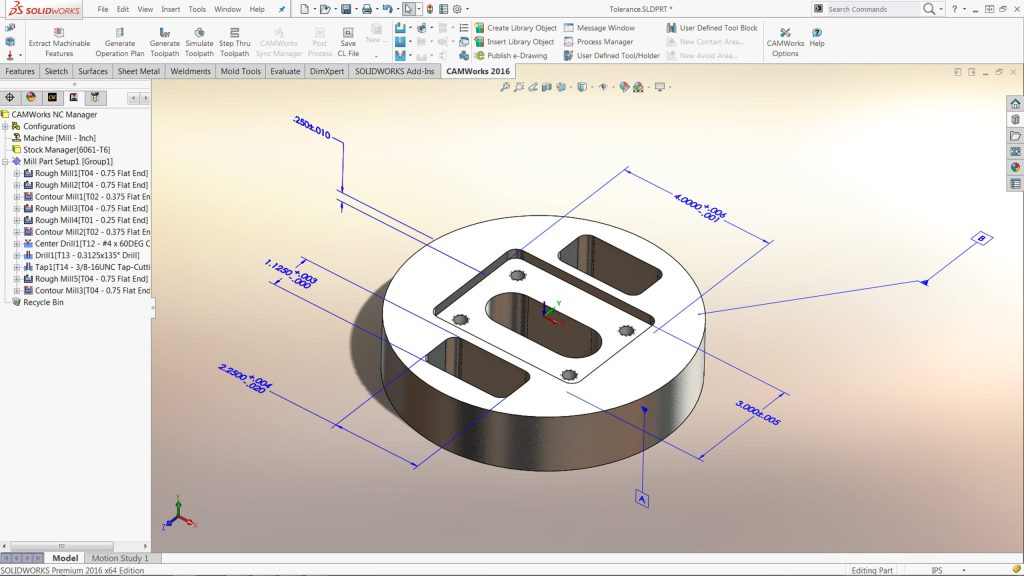

Geometric Ltd. announced the addition of automated "Machine to the Mean" capabilities when working with Solidworks parts and assembly files that contain tolerance—or geometric dimensioning and tolerance (GD&T)—information. These automated mean tolerance calculation capabilities will eliminate the common practice of having to manually calculate allowances when defining CNC toolpaths or the need to rebuild 3D models to mean geometry, thus eliminating potential mistakes, while saving time and money, and streamlining the transition from design to manufacturing.

Geometric Ltd. announced the addition of automated "Machine to the Mean" capabilities when working with Solidworks parts and assembly files that contain tolerance—or geometric dimensioning and tolerance (GD&T)—information. These automated mean tolerance calculation capabilities will eliminate the common practice of having to manually calculate allowances when defining CNC toolpaths or the need to rebuild 3D models to mean geometry, thus eliminating potential mistakes, while saving time and money, and streamlining the transition from design to manufacturing.

Available through an upcoming, second-quarter 2016 point release of CAMWorks 2016 software, the new capabilities eliminate long-standing issues surrounding differences between design practices required to tolerance parts based on fit, form and function vs. manufacturing's need to machine geometry based on mean dimensions and tolerances.

"Every part or assembly that has tolerances designed for specific functional requirements—such as slip fits, press fits, etc.—require tolerance specifications that have different upper and lower or asymmetric limits," explains Jim Foster, Vice President of Global Channel Sales and Marketing at Geometric. "This has long caused extra work for manufacturing professionals because parts are machined to a nominal dimension using methods and tools that provide an equal resulting tolerance on each side of a mean dimension. For years, CNC programmers have had to manually calculate mean dimensions and tolerances and then offset edges and surfaces in the manufacturing model or, rebuild 3D parts to take this into account, a practice that is time-consuming and prone to error."

"With this new capability, CAMWorks 2016 software will automatically calculate the mean dimension and required tolerance for manufacturing and then use this information to select the correct tooling, machining strategy, and generate the toolpath." Foster stresses. "The impact of this solution is that CAMWorks users won't have to rebuild models or add offsets anymore because they will be able to machine to the mean automatically, saving time, reducing costs, and improving quality."