Cincinnati MEGA 800 Horizontal Machining Center

Cincinnati MEGA 800 Horizontal Machining Center

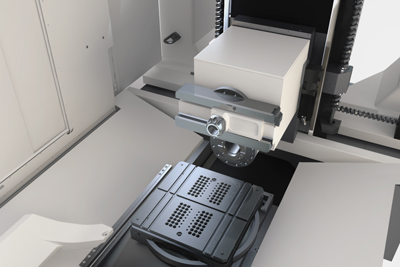

Fives introduces a new integrated contouring head for its Cincinnati 6-axis MEGA 800 HMC by announcing the sale of a two-machine cell that includes first use of the head on this machine size.

Fives introduces a new integrated contouring head for its Cincinnati 6-axis MEGA 800 HMC by announcing the sale of a two-machine cell that includes first use of the head on this machine size. Purchased by a European machine tool manufacturer, the new cell will replace an existing two-machine cell in 24-hour operation, taking on 30 to 50 percent more work, including work currently processed on boring mills. The machines' servo-controlled, U-axis cross-feed spindle can produce circular features up to 540-mm diameter that require turning, boring, co-boring, facing, threading, tapered boring, and helical thread milling. The new MEGA cell eliminates the need to produce these features on other machines, dramatically reducing workpiece transfers, setups and work-in-process inventory, while improving accuracy and manufacturing velocity.

The cell includes a 14-pallet work queue, two vacuum-equipped load/unload stations, storage for 640 tools and floor-mounted mist collection for each machine. Each machine stores 120 tools, while an integrated storage/retrieval system holds an additional 400, which are transferred to the machines via overhead robot.

"The combination of the U-axis head and main W-axis milling/boring spindle eliminates the need for boring machines and turning centers by combining both capabilities in a single multi-tasking machine," said Fives Cincinnati Product Manager Ken Wichman. "The U-axis head produces 2,475 Nm torque (S6-60) and has a Sandvik Coromant Capto C8 tool interface, capable of carrying a tool weight of 30 kg (66 lb). The range, power, accuracy and tool-handling capability of this contouring head give the customer a much wider range of processing capabilities than possible with contouring attachments or other options. The integrated head is much more rigid than attachments bolted on or held by the spindle taper, resulting in superior part quality, surface finish and dimensional accuracy. The standard tool interface eliminates the need for special tools, and the integrated head eliminates manual head changing and storage. This extends the successful integration of this head from the larger Giddings & Lewis HMC 1250 platform."

Both MEGA HMCs in the first sale are equipped with a 4,000-rpm, 45-kW (S6-60 hp) W-axis live spindle with 130mm bar diameter and 800mm travel. The massive machines accept parts weighing up to 2,200 kg (4,840 lb), 2,000mm (79") tall and 1,300mm (51.2") in diameter. The three-point-leveled, T-design base moves the workpiece in a straight line to and from the spindle for precision boring, with X, Y and Z axes all driven by dual ballscrews using absolute scale feedback. The B-axis rotary table with high-accuracy absolute encoder allows infinite contouring, producing 5,100 Nm (3,300 ft lb) torque.

The machines utilize the Siemens 840D Solution Line CNC with Windows 7 OS and operator interface, and the cell complies with all European and U.S. safety/health standards.