Contact Details

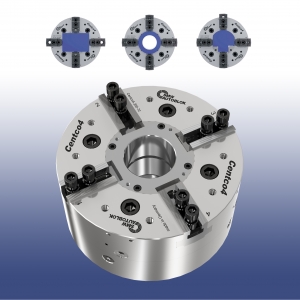

SMW Autoblok introduces the hybrid COMOT-AZ quick change collet chuck featuring industry standard diameter capacities of 42 mm, 65 mm, and 100 mm to accommodate a large variety of workpiece sizes. Ideal for bar and tubular stock machining that requires multiple changeovers daily, COMOT-AZ can be used in three ways: for OD machining using standard collets, for greater accuracy utilizing high precision collets with COMOT-AZ/PA or, transform COMOT-AZ quickly into an expanding mandrel for ID clamping using the EMX series.

Effectively used for hard turning, gear grinding, drilling, milling and more, COMOT-AZ provides low deformation clamping of thin-walled workpieces and offers a large selection of standard collets available in round, square, hexagonal, and special configurations when needed for virtually all sizes of spindles.

The optional COMOT-AZ/PA enables users to change from a standard collet to a high precision collet for holding workpieces from 3 mm to 100 mm with superior accuracy and repeatability. The EMX Series extension mandrel is also available for internal workpiece fixturing.

For automated loading, COMOT-AZ also provides air sensing to ensure that the part is seated properly before the machine cycle starts. Other advantages include radial fine adjustment and a case-hardened body and internal parts for high resistance and longer life.

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- hard turning

hard turning

Single-point cutting of a workpiece that has a hardness value higher than 45 HRC.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

- mandrel

mandrel

Workholder for turning that fits inside hollow workpieces. Types available include expanding, pin and threaded.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- outer diameter ( OD)

outer diameter ( OD)

Dimension that defines the exterior diameter of a cylindrical or round part. See ID, inner diameter.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS