Contact Details

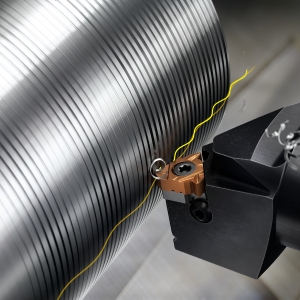

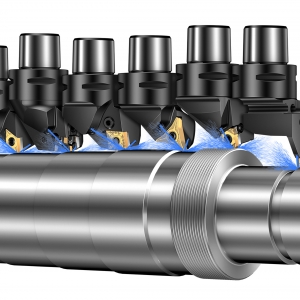

Sandvik Coromant is launching a deep-hole machining concept for the STS system, CoroDrill 808. Among its many features, this product is equipped with optimized pad design for good hole finish, unique edge preparation for increased chip breaking and a reinforced periphery insert corner for added security and reliability. Suitable for diameters from 15.60 to 65.00mm (0.614 to 2.559 inch) and tolerance demands of IT 9, CoroDrill 808 is capable of producing perfect holes, regardless of the component material.

Being suitalbe for close-tolerance holes, CoroDrill 808 is ideal for the energy segment, for example, when machining in heat exchanger plates, according to the company. Cladded materials such as low-carbon steel with Inconel, used for these types of applications, are difficult to machine due to tricky chipbreaking and tool life maintenance. Thanks to a specially designed geometry and grade technology, CoroDrill 808 produces superior close-tolerance holes even in the toughest conditions. In addition, this drill is available as a stock standard item with 24-hour delivery.

CoroDrill 808 premium drills are equipped with a fully traceable dot matrix. It is a two-dimensional patterned array, used for storage and display of various types of information, for example, the measurement protocol. Such protocol includes data on diameter and run out of the drill, making dot matrix a very safe tool for product identification and traceability.

Related Glossary Terms

- edge preparation

edge preparation

Conditioning of the cutting edge, such as a honing or chamfering, to make it stronger and less susceptible to chipping. A chamfer is a bevel on the tool’s cutting edge; the angle is measured from the cutting face downward and generally varies from 25° to 45°. Honing is the process of rounding or blunting the cutting edge with abrasives, either manually or mechanically.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

PRODUCTS

PRODUCTS