Contact Details

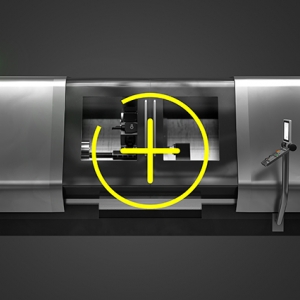

In a move designed to greatly improve efficiency and quality in CAM operations, CoroPlus ToolLibrary and PrimeTurning method from Sandvik Coromant have been integrated in Mastercam 2018. The CoroPlus suite of connected solutions from Sandvik Coromant facilitates digital machining, providing access to real-time process insights and data. Mastercam is the first CAM software to integrate solutions for both CoroPlus ToolLibrary and PrimeTurning technologies.

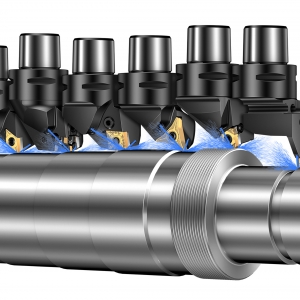

CoroPlus ToolLibrary is a digital tool library that removes the need for users to browse catalogs and web pages to find the required tool data. It also allows users to import tool assemblies directly into their CAM system and provides access to tool catalogs containing perfect digital representations of the physical tools. The planning of machining operations using the exact dimensions and models of the tools enables accuracy in CAM programming, thus reducing the risk of collisions during machining. Additional benefits include the considerable time savings created by eliminating the need to search catalogs and other sources for references. Furthermore, assurance is provided that different tool items will always fit together.

Users can find the tool simply by inputting the tool ordering code or using filter commands. The finished assemblies are then imported into Mastercam 2018 with the click of a button, ready for programming and simulation.

“Selecting the right combination of tool holder, tool body and inserts is simplified and expedited using CoroPlus ToolLibrary,” says Pernilla Lindberg, product manager for CoroPlus ToolLibrary. “The library functionality is based on the ISO13399 tool data standard that permits users to import tool assemblies directly into their CAM package.”

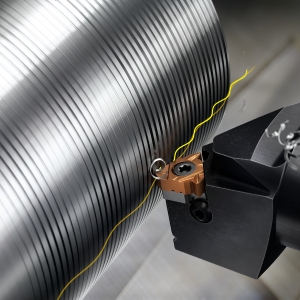

Another part of the new Mastercam release is an option for PrimeTurning. PrimeTurning software enables quick and accurate programming of PrimeTurning, a new methodology that allows machine shops to turn components in all directions with a single tool. CNC Software, developers of the Mastercam software, have partnered with Sandvik Coromant to ensure that CAM users can create programs for PrimeTurning within Mastercam.

“To ensure that machine shops maximize the benefits and huge potential of PrimeTurning, correct and smart programming is required, as well as optimized and easy tool selection,” says Mia Pålsson, senior manager, turning tools. “Helping to optimize manufacturing processes is a core focus at Sandvik Coromant; we are not just a cutting tool manufacturer; we help machining companies to be more efficient at the planning stage. We are, therefore, proud to work together with CNC Software to support our common end users.”

Meghan West, president of CNC Software, adds: “We are thrilled to partner with Sandvik Coromant to help bring these innovations to the market. It is exciting that our users will be some of the first to benefit from these industry breakthroughs. With the widest installed base of any CAM system, we’re eager to see the many ways Mastercam users will capitalize on these advancements.”

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.

PRODUCTS

PRODUCTS