Contact Details

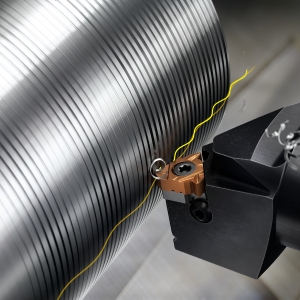

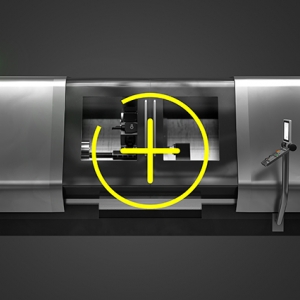

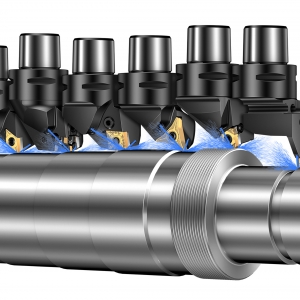

Sandvik Coromant's recently introduced insert grade GC1125 is now complemented with the new grade GC1135. The new grade offers exceptional quality for threading operations, according to the company. Both grades offer good function in ISO materials but each has its own specialty. GC1125 is ideal for threading operations in steels, cast irons and aluminum, while GC1135 excels in stainless steels, super alloys and profiles requiring sharp cutting edges. Additionally, the GC1125 and GC1135 are available in the new 16mm insert for CoroThread 266. The 3/8 inch (16mm) size insert is suitable for the majority of general threading applications and benefits from the unique iLock interface with its secure insert clamping. This exceptional stability improves the threading performance with greater precision and fewer passes.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- cast irons

cast irons

Cast ferrous alloys containing carbon in excess of solubility in austenite that exists in the alloy at the eutectic temperature. Cast irons include gray cast iron, white cast iron, malleable cast iron and ductile, or nodular, cast iron. The word “cast” is often left out.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

PRODUCTS

PRODUCTS