Cranfield Precision TTG Machine

Cranfield Precision TTG Machine

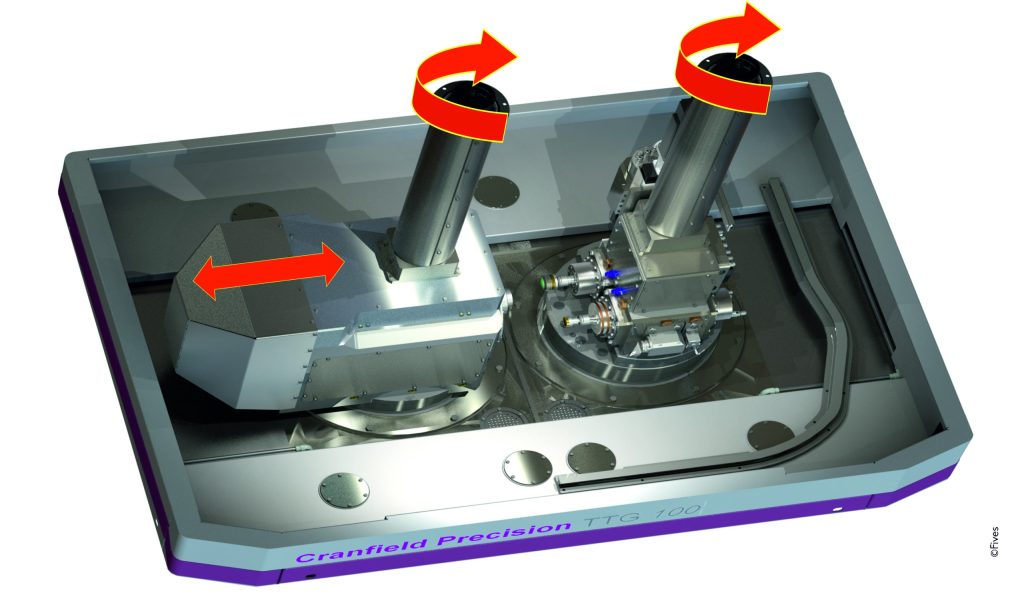

Fives says the new Cranfield Precision TTG machine is a radically new concept. While conventional machine tool platforms use stacked linear axes as the primary motion control system, the Cranfield Precision range coordinates two rotary axes and a short linear axis in a "twin-turret" design.

Fives says the new Cranfield Precision TTG machine is a radically new concept. While conventional machine tool platforms use stacked linear axes as the primary motion control system, the Cranfield Precision range coordinates two rotary axes and a short linear axis in a "twin-turret" design. It uses a unique (and patented) combination of rotary and linear axes to produce relative motion (both position and angle) between tool and workpiece over a swept working area.

Compared to conventional machines, the Cranfield Precision platform offers two main advantages:

Stiffness, because the new machine base is effectively two rotary, highly damped hydrostatic bearings that resist machining forces, and thermal stability, because the twin-turret design enables a simple non-contacting labyrinth seal, making the machine base almost immune to distortions. These are usually caused by the heat generated from constantly changing coolant return path as the grinding wheel carriage moves along the linear axis.

This design provides a common platform for multiple machine configurations and processes, including OD grinding, ID grinding, profile grinding, milling, polishing, hard turning, diamond turning dicing and in-situ metrology.

The machine is supplied in two sizes: TTG100 and TTG400 for up to 100mm-dia. and 400mm-dia. components, respectively.

The trend towards superabrasives demands a highly stiff and thermally stable machine geometry. The new design of this Cranfield Precision machine reportedly responds to the needs of the most demanding applications looking for extreme accuracy in their grinding processes:

The optics industry for grinding spherical, aspheric and free-form surfaces on a variety of materials.

Universal CNC grinding of more conventional parts held in a chuck or faceplate using aluminum oxide or superabrasives.

The experiences gained by Fives over many years for its Cranfield Precision range of products in the optic industry show that ductile regime grinding of brittle materials can deliver considerable process advantages over conventional grinding processes. This mode of operation is not possible to support unless the machine system is extremely stiff, highly damped and capable of submicron position control.