Danobat DS3A

Danobat DS3A

Pat Mooney Saws, the U.S. dealer for DANOBAT bandsaw machines, offers the DANOBAT DS3A, a bandsaw designed to cut up to 13" capacity.

Pat Mooney Saws, the U.S. dealer for DANOBAT bandsaw machines, offers the DANOBAT DS3A, a bandsaw designed to cut up to 13" capacity.

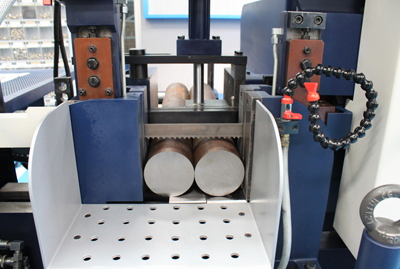

DANOBAT DS3A is for cutting hard-to-cut materials such as Inconel, stainless steel and nickel alloys. This machine is characterized by accuracy and heavy construction with the aim of ensuring productivity, extended blade life and cutting quality, according to the company.

Two columns are designed to accept high blade tension. The material is clamped on both sides of the blade to reduce burrs. The movable arm is automatically adjusted to the width of the material and is positioned in the optimal position in relation to the moving vice. This ensures the saw blade is supported as close as possible to the material on both sides of the cut.

Blade guidance is accomplished by bearings and plates fitted on plate holders. This allows realignment of the blade position, while the automatic arm avoids manual adjustments.

Feeding of material by moving the vice is incremental, thereby eliminating the need for the feeding vice to continuously move to the preset feed position. Results are faster cycle times and higher productivity.

Cutting Capacity: Round 13"; Square 13" x 13"; Bundles 13" x 8.3"

Blade Dimensions: 195" x 1.3" x 0.04"

Blade Speed: 46-295 fpm