DMC 65 H monoBLOCK Horizontal Machining Center

DMC 65 H monoBLOCK Horizontal Machining Center

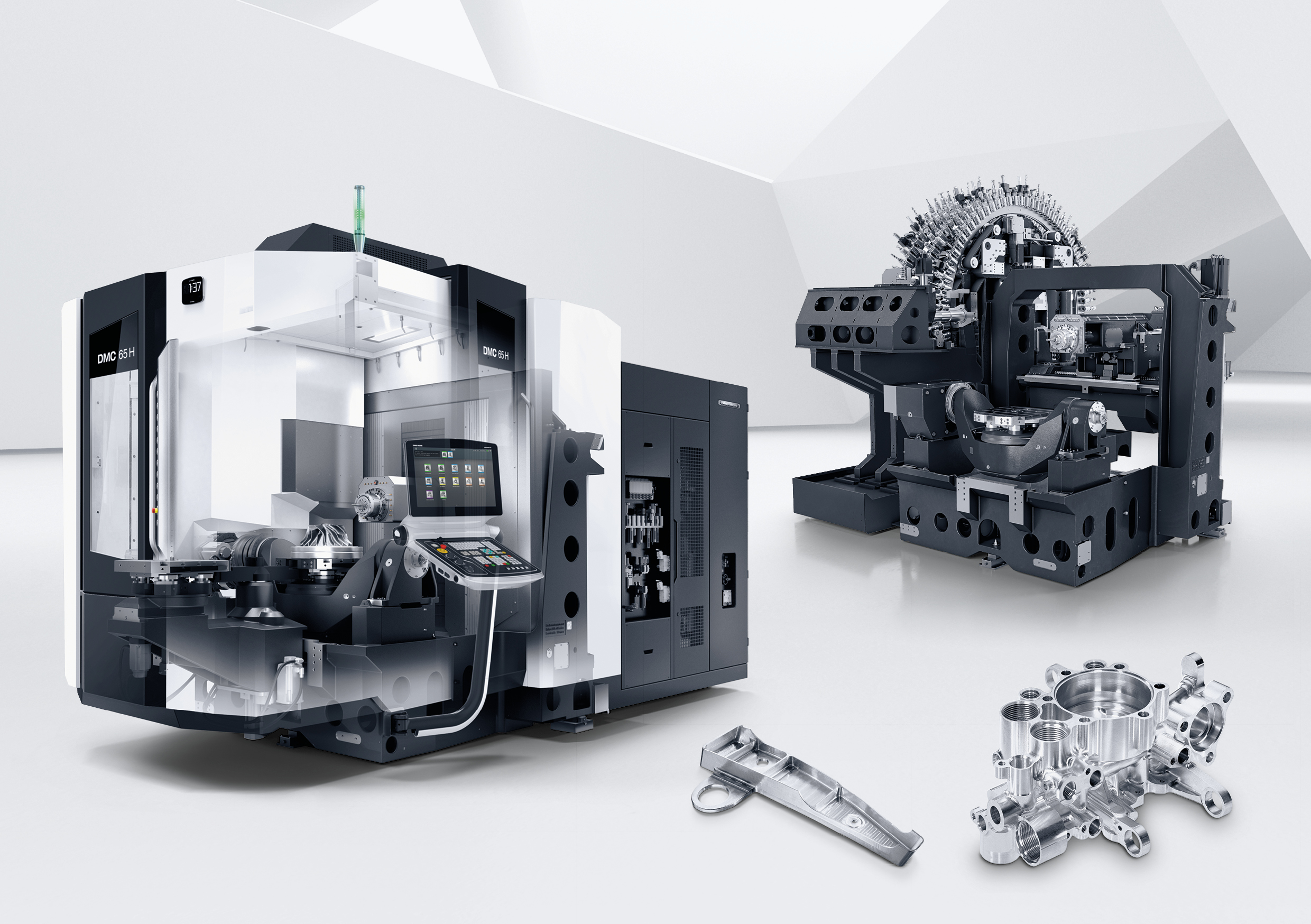

With the DMC 65 H monoBLOCK, DMG MORI presents a new highlight in horizontal machining. The unique machine concept unites the flexibility and ergonomics of a 5-axis vertical machine with the productivity and process reliability of a horizontal machining center.

With the DMC 65 H monoBLOCK, DMG MORI presents a new highlight in horizontal machining. The unique machine concept unites the flexibility and ergonomics of a 5-axis vertical machine with the productivity and process reliability of a horizontal machining center.

The optimal chip fall makes the new machine particularly suitable for process-reliable machining of aerospace structural components. People working in the area of dies and molds benefit from the possibility of machining components directly with deep-hole bores of up to 550 mm on one machine.

Contract manufacturers in particular value the flexibility provided by the swivel rotary table mounted on both sides and the ingenious workspace. This makes it possible to machine both high clamping towers and 5-axis components weighing up to 600 kg. The thermo-symmetric construction of the inherently rigid machine bed, including three-point support, ensures maximum long-term accuracy.