ESPRIT 2011 CAM Software

ESPRIT 2011 CAM Software

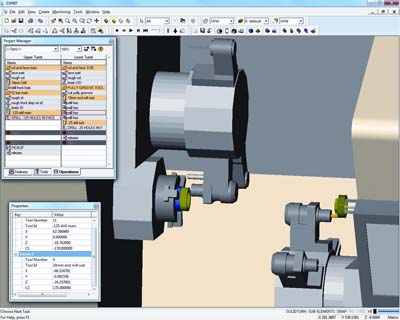

ESPRIT 2011, the latest release of computer-aided manufacturing software from D.P. Technology, features system-wide upgrades that are of benefit to all programmers, and includes new, innovative, productivity-enhancing technology for CNC programmers of mills, lathes and wire EDM machines.

ESPRIT 2011, the latest release of computer-aided manufacturing software from D.P. Technology, features system-wide upgrades that are of benefit to all programmers, and includes new, innovative, productivity-enhancing technology for CNC programmers of mills, lathes and wire EDM machines.

The ESPRIT CAM system is capable of machining any part geometry (solid, surface or wireframe), universal post processing to format G-code for virtually any machine tool, and solid simulation and verification with dry runs rendered in dynamic solids for optimal part quality and consistency