Contact Details

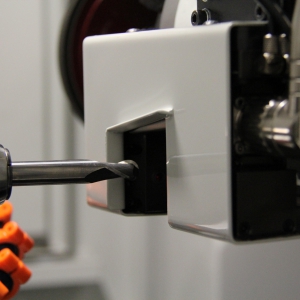

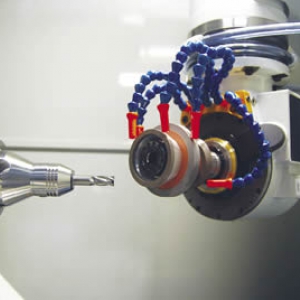

ANCA offers the FCP4 high-production drill grinder (FCP4). Producing drills from 0.8 to 4mm with the new technology provides an exciting opportunity for drill makers, with important efficiencies and cost benefits by manufacturing a complete HSS drill on a single machine, according to the company. From a blank piece of raw material, the FCP4 grinds the flute, relief and point, producing a finished drill.

Grant Anderson, CEO at ANCA said: “Considering the yearly production of high speed steel drills is about 1.8 Billion drills, the opportunities are huge. The high-volume commodity drill market is a new market for us but is a great fit given our forty plus years’ expertise in tool and cutter grinding and our world leading technology.”

The new machine will enable a complete drill to be manufactured every 20 to 25 seconds. Up until now, a drill has typically been manufactured on two or three separate machines, which is a large investment to make and a big task in changing drill sizes - often taking several hours and creating needless waste with scrap setup drills. The CNC capability of the FCP4 also has significant advantages in quicker changeover and less setup times required, making the option of smaller production runs viable.

“We think we can bring a huge benefit to the industry as up until now there is little competition or product choice for volume manufacturers of HSS drills. Drill manufacturers are typically restricted to using machines that are old and cam-operated, and with older machines wearing out there are currently very few options for upgrading or improving their capabilities,” Grant continued.

Simon Richardson, FCP4 product manager said: “We listened to our customers who, in this market, faced a lack of choice and responded to their needs to develop our own solution. With our extensive market knowledge and research and development capabilities, I am confident this new machine will be well received and unleash a whole new world of possibilities for our customers.”

The FCP4 will be fully CNC operated comprising of eight axes, using a principle similar to a Swiss auto, whereby it has a multiturret, capable of undertaking several operations simultaneously. It uses an ANCA Motion CNC system including AM5C drives, AMI5000 Touchpad, Commander, AMCore and Motion Bench.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- high-speed steels ( HSS)

high-speed steels ( HSS)

Available in two major types: tungsten high-speed steels (designated by letter T having tungsten as the principal alloying element) and molybdenum high-speed steels (designated by letter M having molybdenum as the principal alloying element). The type T high-speed steels containing cobalt have higher wear resistance and greater red (hot) hardness, withstanding cutting temperature up to 1,100º F (590º C). The type T steels are used to fabricate metalcutting tools (milling cutters, drills, reamers and taps), woodworking tools, various types of punches and dies, ball and roller bearings. The type M steels are used for cutting tools and various types of dies.

- relief

relief

Space provided behind the cutting edges to prevent rubbing. Sometimes called primary relief. Secondary relief provides additional space behind primary relief. Relief on end teeth is axial relief; relief on side teeth is peripheral relief.

PRODUCTS

PRODUCTS