Contact Details

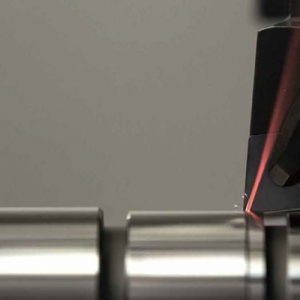

FINE BEAM incorporates precision insert and guide pad designs to make it possible for high precision deep hole drilling at high speeds and feeds.

The latest additions include inserts with 0.8 mm (.032″) nose radius in versatile AH725 grade. 0.8 mm nose radius will provide the cutting edge with strength, preventing edge fracture for predictable tool life. In addition, AH725 enhances the insert’s wear resistance during machining of various materials, ensuring high precision and boosts productivity.

At a Glance

- 0.8 mm nose radius provides the cutting edge with fracture resistance, preventing micro-chipping on the cutting edge

- AH725 grade provides tool life predictability in machining various materials

- Productive solution for producing high precision deep holes

- 5 new inserts are added in this expansion

Related Glossary Terms

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS