Forte Rotary Broaches

Forte Rotary Broaches

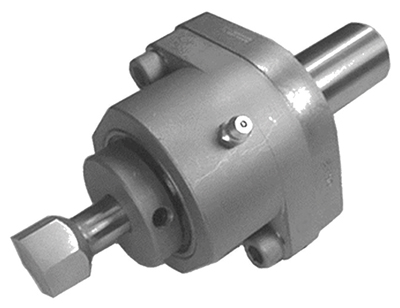

Somma Tool Co., a manufacturer of rotary broaching tools and holders, announces a new line of broaches called Forte.

Somma Tool Co., a manufacturer of rotary broaching tools and holders, announces a new line of broaches called Forte.

Forte broaches are made of a tough broaching material. It is the company's new standard stock material replacing M2.

Forte has a high wear resistance, resulting in better tool life plus no chipping, according to the company.

The Forte broaches take a deep depth of cut and can be used in non-Somma broach holders as well.

ANSI hex and square broaches are stocked for same day shipping. Special "to print" sizes are available in 1-2 days.