Contact Details

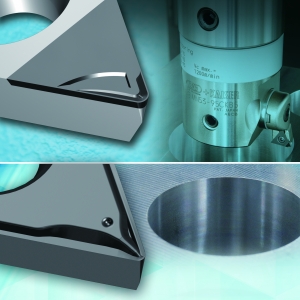

BIG KAISER introduces the Fullcut Mill Contact Grip, an endmill that permits easy indexing of cutter heads while maintaining excellent rigidity and accuracy. With the addition of the Fullcut Radius Mill (FRM) and the Ball End Mill (BE), the Fullcut Mill Contact Grip series now features four connection sizes and seven cutter types.

The unique dual Contact Grip of the Fullcut Mill Contact Grip is a threaded coupling system that achieves machining capacity close to that of integrated types. The taper and flange face make close contact for solid connection and one holder allows selection from multiple heads.

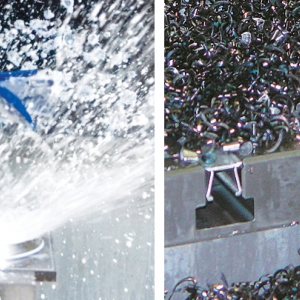

The FRM includes round inserts with high rake for low cutting resistance, making it ideal for ramping and helical milling applications. The BE is solid CrN-coated carbide for superior wear resistance and is available with two or three flutes in diameters of 16, 20 or 25 millimeters.

Indexable endmills are usually known for rough milling. However, other cutters in this series, like the Fullcut Mill FCM Type for profile milling, are designed to realize sharp cutting and low cutting resistance, thanks to the versatile dual-contact Contact Grip design. Similarly, the Fullcut Mill FCR Type heads are multifunction 3D cutters suited for both heavy and stable ramping. Also part of the series are three chamfering options, the C-Cutter Mini for transverse chamfering, the C-Cutter for plunge chamfering and the C-Cutter Universal for adjustable angle chamfering.

Related Glossary Terms

- chamfering

chamfering

Machining a bevel on a workpiece or tool; improves a tool’s entrance into the cut.

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS