GEN3SYS XT Pro High-Penetration Insert

GEN3SYS XT Pro High-Penetration Insert

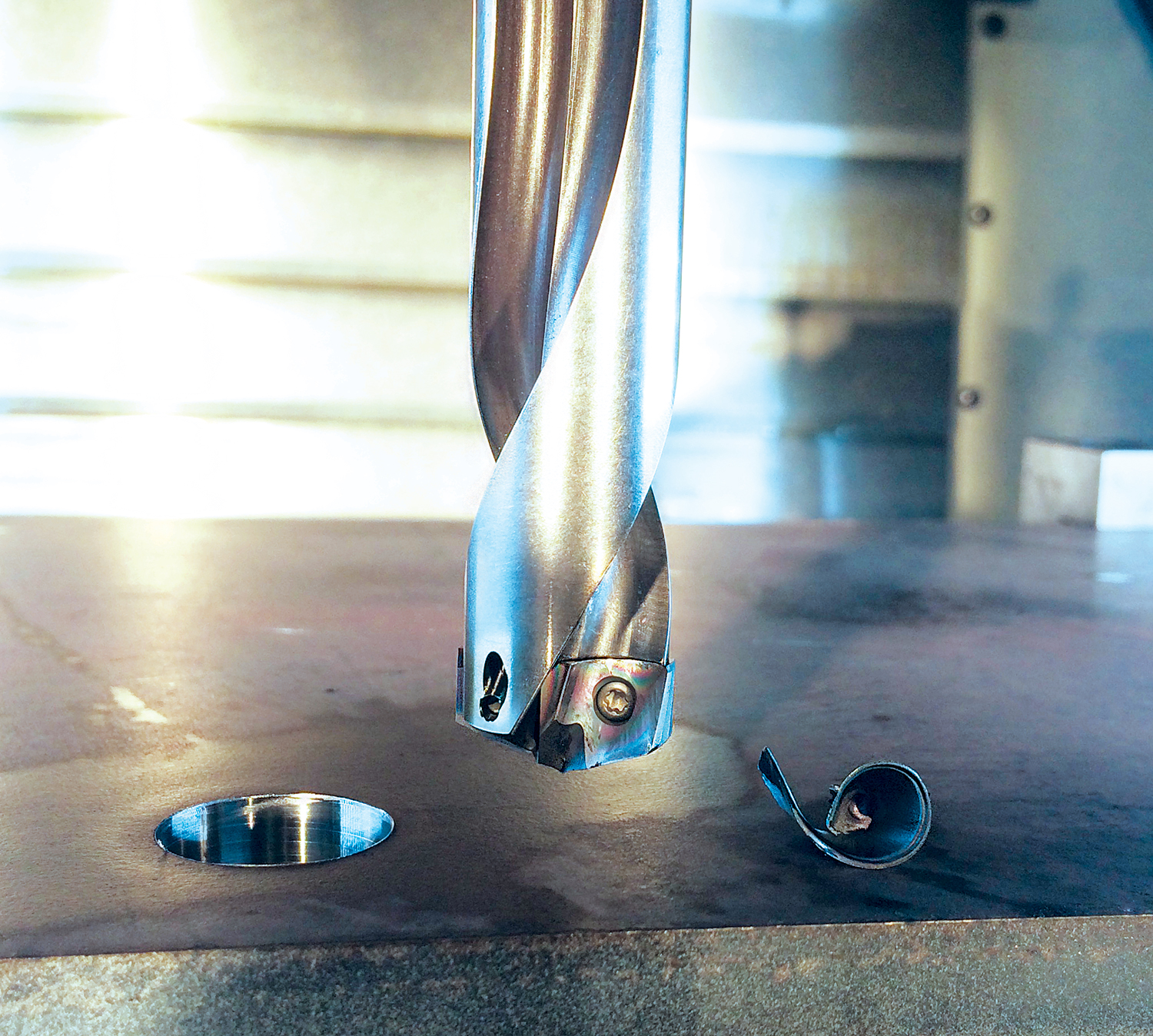

Allied Machine & Engineering announces the release of its newest GEN3SYS XT Pro high-penetration insert designed specifically for beam and plate production in the structural steel market. With an exclusive combination of substrate and multilayer coating, the insert is engineered to withstand heat generated while drilling in structural steel beams or plates in high production facilities.

Allied Machine & Engineering announces the release of its newest GEN3SYS XT Pro high-penetration insert designed specifically for beam and plate production in the structural steel market. With an exclusive combination of substrate and multilayer coating, the insert is engineered to withstand heat generated while drilling in structural steel beams or plates in high production facilities. Optimized in its existing structural steel holders, Allied's high-tech structural steel insert improves chip formation and reduces vibrations creating a higher-quality hole.

The unique composition of carbide grade, geometry and high-temp coating are designed to run at or beyond current OEM rates while offering extended tool life. The insert's simplified setup and extended tool life reduces changeover and increases throughput.

"During beta testing customers reported significant reduction in noise as well as less signs of heat." Explains Andrew Pisorn, product manager for Allied's GEN3SYS XT Pro product line. "We've optimized the design of this particular insert to give machine shops and manufacturers a competitive advantage in structural steel holemaking. From better run rates and less tool failures, the stability of this insert provides increased capacity and most importantly increased profit for the customer."