GPEL-30.25 CNC Eccentric Pin Grinder

GPEL-30.25 CNC Eccentric Pin Grinder

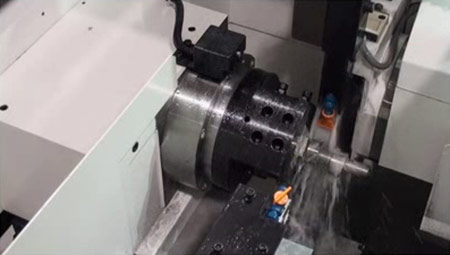

If tight tolerances and surface finishes are everyday work for you, the GPEL-30.25 meets your most demanding process requirements for quality, flexibility, and productivity. Powerful, user-friendly control and a highly reliable spindle are standout attributes of this new high-speed eccentric pin grinder.

The GPEL-30.25 excels at high-production grinding applications, processing a diverse range of materials with speed and precision. Shigiya's advanced user interface and CNC technology bring the extremely close tolerances, short cycle times, and versatile machining capabilities needed in today's manufacturing environment.

The GPEL-30.25 combines a swing over table of 300 mm and a maximum workpiece length of 250 mm. The Shigiya design incorporates a built-in wheel spindle motor to reduce wheelhead weight. Shigiya also adopted a linear motor for wheelhead feed and high-output built-in servo motor for work spindle rotation, resulting in fast, stable grinding.

Accurate to 1 micron, the GPEL-30.25 features simultaneous two-axis control of the wheelhead feed (X-axis) and the work spindle rotation (C-axis). Workpieces are centrally clamped and machined with stable X-axis and C-axis control. The linear motor in the X-axis controls the eccentric. Furthermore, the table traverse type delivers high-precision grinding.

Shigiya emphasizes automated systems in the GPEL-30.25 for reliability and ease of operation. Machine operators can program all the pin diameters in one setup.