Contact Details

UNITED GRINDING North America announced today the expansion of their extensive range of grinding and measuring equipment with seven new products being unveiled by three of the company's brands.

STUDER has brought two new cylindrical grinding machines to the North American market with the release of the S100 and S36. The S100 is a universal internal cylindrical grinding machine and the newest member to the "entry-level" family, and is a perfect way for job shops to get into cylindrical grinding or upgrade their older grinding machines with the latest technology. The S36 is the newest OD production grinding machine that has a modified wheelhead to accept a large grinding wheel with a diameter of up to 24” and a width of nearly 5”.

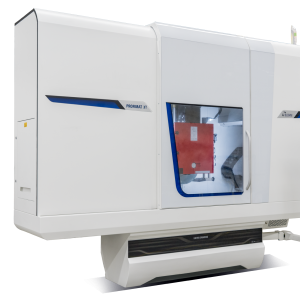

BLOHM continues its tradition of customer-centric surface and profile grinding innovation with the release of the PLANOMAT XT Essential. This 3-axis grinding machine is BLOHM’s entry-level offering for job shops who are eyeing CNC grinding but need a more attainable starting point. BLOHM is also adding a new option on a powerhouse creep feed grinder: the PROFIMAT XT is now available with a tool changer, enabling the automatic changing of grinding wheels.

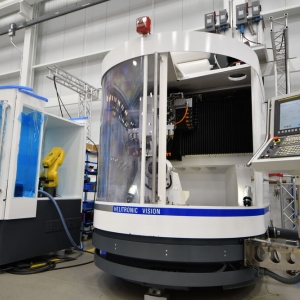

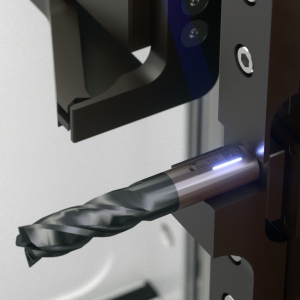

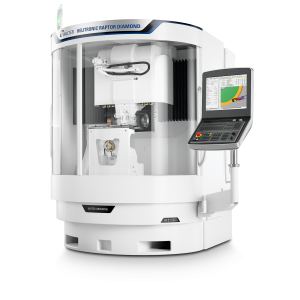

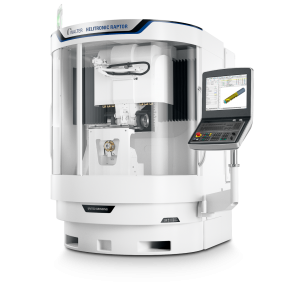

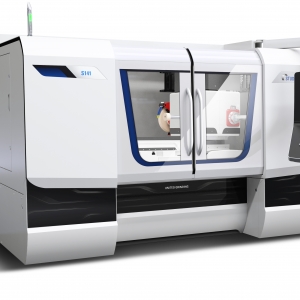

WALTER is focused on packing more tool grinding functionality into a compact space with the new HELITRONIC G200 and HELITRONIC MINI PLUS. The HELITRONIC G200 gives cutting tool makers and contract manufacturers an entry point into the regrinding market, and offers an economical solution for the production of small-to-medium-sized tools. If these manufacturers require a higher volume of production of the same-sized tools, the HELITRONIC MINI PLUS is the perfect place to start the conversation. Additionally, the all-new HELICHECK PLUS now comes with an available 3D sensor, which adds the capabilities of the popular HELICHECK 3D model right into the PLUS model. The 3D sensor enables this machine to laser-scan a tool and generate a 3D model made up of as many as 3 million individual points.

“New technologies from our brand companies overseas, paired with recent innovations from our own team here in Miamisburg, are helping our customers realize strong productivity gains and an ability to support a wider array of applications," said Markus Stolmar, President and CEO of UNITED GRINDING North America. “Our commitment to bringing the best technology to market is stronger than ever, and I am truly excited for the future.”

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- cylindrical grinding

cylindrical grinding

Grinding operation in which the workpiece is rotated around a fixed axis while the grinding wheel is fed into the outside surface in controlled relation to the axis of rotation. The workpiece is usually cylindrical, but it may be tapered or curvilinear in profile. See centerless grinding; grinding.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding machine

grinding machine

Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpiece surfaces. When ultrasmooth surfaces and finishes on the order of microns are required, lapping and honing machines (precision grinders that run abrasives with extremely fine, uniform grits) are used. In its “finishing” role, the grinder is perhaps the most widely used machine tool. Various styles are available: bench and pedestal grinders for sharpening lathe bits and drills; surface grinders for producing square, parallel, smooth and accurate parts; cylindrical and centerless grinders; center-hole grinders; form grinders; facemill and endmill grinders; gear-cutting grinders; jig grinders; abrasive belt (backstand, swing-frame, belt-roll) grinders; tool and cutter grinders for sharpening and resharpening cutting tools; carbide grinders; hand-held die grinders; and abrasive cutoff saws.

- grinding wheel

grinding wheel

Wheel formed from abrasive material mixed in a suitable matrix. Takes a variety of shapes but falls into two basic categories: one that cuts on its periphery, as in reciprocating grinding, and one that cuts on its side or face, as in tool and cutter grinding.

- outer diameter ( OD)

outer diameter ( OD)

Dimension that defines the exterior diameter of a cylindrical or round part. See ID, inner diameter.

PRODUCTS

PRODUCTS