H Series Horizontal Machining Centers

H Series Horizontal Machining Centers

HELLER Machine Tools introduces the top range of its 4-axis H Series horizontal machining centers, the H 14000.

HELLER Machine Tools introduces the top range of its 4-axis H Series horizontal machining centers, the H 14000. This large capacity machine combines a super-robust machine design with the structural stiffness and high torque required for making the deepest cuts in the toughest alloy steels and irons. Developed and perfected over many years as the number one machine provider for large diesel engine component machining solutions Heller's H series is for machining large pumps and housings for power and fluid transmission.

The capacity of the H Series machines to make roughing cuts while still providing finishing accuracies for XYZ positioning of 0.010mm (according to VDI/GDQ 3441) make them ideal for large, difficult to machine alloy steel and iron components, according to the company. Feed forces of 20,000 N make it capable of making demanding cuts.

The Heller H 14000 is the top of the H-series, featuring a work area of 2400x1600x1600mm in X/Y/Z over a 1000mm pallet capable of handling a 4000kg workpiece load. HELLER has also minimized positioning times by focusing on realistic dynamic rates of 40 M/min in all axes.

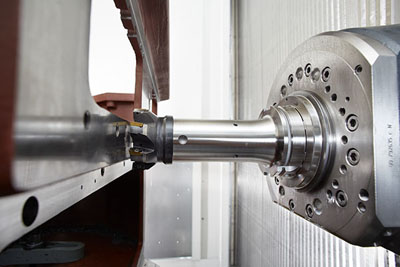

Heller's NC out-facing head is available on the H 14000 for performing feed out operations on the machine such as taper boring, generating pockets, as well as compensating diameters. A measuring probe for on-machine part checking, and instant tool breakage monitoring are integrated. The machines, consistent with efficient cell operation are designed for manual or can be easily adapted to FMS systems or other automated loading systems.

With a high power cutting (HPC) gear-driven head stock, the H 14000 offers maximum torque of 2292 NM and generating 60 kW of power at low rpm with options available for rigid face clamping for right angle milling heads. HSK 100 spindle taper is standard with a choice of chain type tool magazines for tools up to 800mm length or rack type magazines with tool lengths up to 1000mm. The precision provided by all machine sizes in the H range is ensured through reduced table deformation and high precision due to internally arranged drives and linear scales. This provides high productivity and minimal axes positioning times resulting in reductions in machining times between 20 and 50 percent in practical application compared to competitive machines.

The H 14000 is designed with three chip augers that rapidly move chips out of the work area and into the chip conveyor, delivering the chips to the chip hopper. To support its global customers, Heller machines are equiped with either Siemens Sinumerik 840D or FANUC 31i-B CNC.