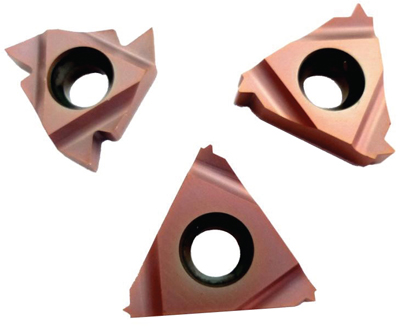

HBA Carbide Grade Inserts

HBA Carbide Grade Inserts

As more applications demand use of superhard alloys, manufacturers are demanding tooling that can deliver precision threads and high production in less time. To meet these challenges, Carmex Precision Tools Ltd. has engineered carbide grade HBA, an extra-fine, submicron grade with high toughness for optimized performance on hardened steel and cast iron up to 62 HRC, as well as titanium alloys and superalloys, including Hastelloy, Inconel and nickel-base alloys.

As more applications demand use of superhard alloys, manufacturers are demanding tooling that can deliver precision threads and high production in less time. To meet these challenges, Carmex Precision Tools Ltd. has engineered carbide grade HBA, an extra-fine, submicron grade with high toughness for optimized performance on hardened steel and cast iron up to 62 HRC, as well as titanium alloys and superalloys, including Hastelloy, Inconel and nickel-base alloys.

Available for internal and external threading in both 60 degree and 55 degree partial profile, as well as ISO metric and UN, HBA delivers high wear and heat resistance and excellent edge stability, according to the company. The unique combination of carbide substrate, coating type and edge conditions enhance performance over extended tool life. In a recent test involving an external right-hand thread: M32x1.5 and a length of 65mm in hardened steel D2: 53-56 HRC, a 16 ER 1.5 ISO grade HBA insert operated at 45 m/min at 28 passes produced 36 threads per corner.

According to Jeff Dei, president of Carmex USA, "Hard machining is increasingly becoming the rule rather than the exception in complex part production. Carmex HBA was engineered to meet the challenges inherent in threading hard materials while delivering high production and longer tool life. We invite our customers and others to bring us their most challenging applications and discover the benefits of engineered carbide performance."