hyperMILL 2014.2 CAM Software

hyperMILL 2014.2 CAM Software

hyperMILL 2014.2 is the latest release of the high-end CAM software from OPEN MIND Technologies AG.

hyperMILL 2014.2 is the latest release of the high-end CAM software from OPEN MIND Technologies AG. In addition to a number of new functions, there are also many enhancements to existing functions.

OPEN MIND is releasing the second version this year to live up to expectations to offer users one of the most innovative CAM solutions. In addition to a key extension for solid modelling in hyperCAD-S, the CAD part of the system, hyperMILL 2014.2 features a range of improvements for CAD programmers and machining.

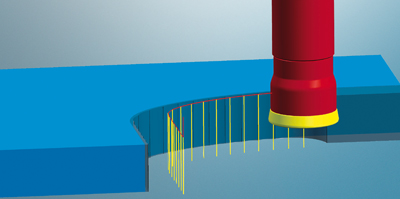

When it comes to Z-level finishing, CAD systems usually simply follow the X and Y coordinates, according to the company. If the bottom surface is curved, the milling result is not optimal and it is necessary to perform a number of rework machining steps. A new function for 3D shape Z-level finishing makes it possible to reference curved bottom surfaces, after which the milling paths are aligned. As a result, the milling tool nestles optimally along the boundary edge between the bottom and the wall. All intermediate levels are offsets of the bottom plane.

OPEN MIND soft bounding concept is also integrated into this new function. This ensures that the boundaries to adjacent surfaces are calculated more precisely and that sharp outer edges are machined more smoothly. User benefits include an optimised finish and reduced programming and machining times.

The open, deep, steep and flat areas of cavities can be machined in one job with collision avoidance. The rest material areas that are recognised during the collision avoidance are transferred automatically to the subsequent job. To this end, optimal tool selection and positioning once again take place. For example, a longer tool or modified position. This process is repeated until the required contour is achieved. Work here has been greatly simplified for CAM programmers.

hyperMAXX, the high-performance cutting (HPC) module for hyperMILL, was also supplemented in some places. This includes plunging the milling tool into the material at pre-drilled holes. This saves 'ramping-in' of the milling tool at the start of machining. The greatest advantage of this method is that it protects tools, particularly in materials that are difficult to cut. The machining process is also collision-checked. Furthermore, it is now possible to select a zigzag mode in hyperMAXX. This mode is particularly suited to machining large workpieces, as it prevents time-consuming repositioning movements, thereby significantly shortening machining times.

2D plunge milling is another new feature. Here, material is removed solely by plunging a milling tool. The new cycle is suitable for both roughing and finishing. The advantage here once again lies in the fast machining and particular suitability for materials that are difficult to cut.