IMCO POW-R-FEED M934 End Mills

IMCO POW-R-FEED M934 End Mills

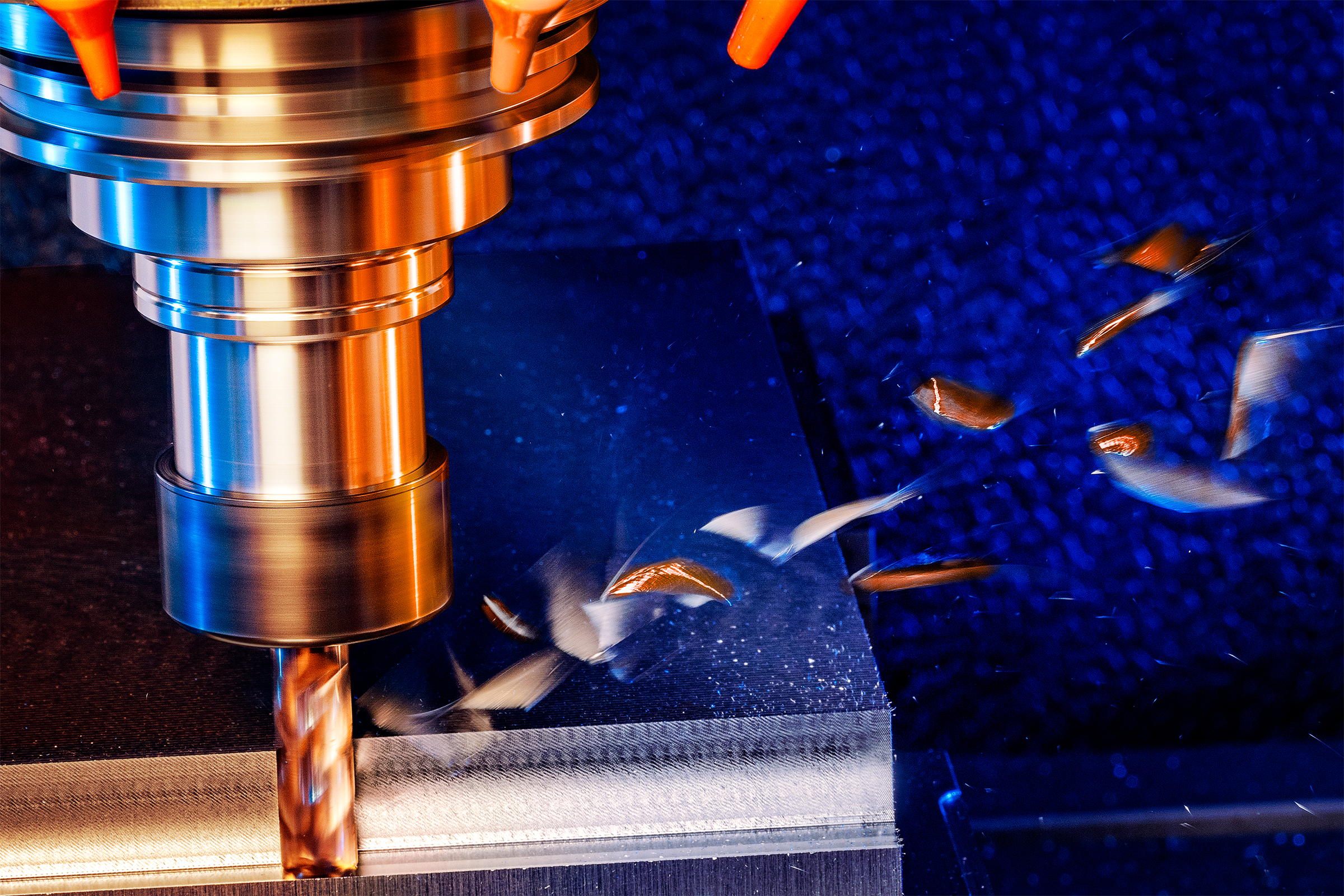

Discover the new IMCO POW-R-FEED M934 end mills, designed for high-efficiency machining with improved chip flow and optimized performance across various materials.

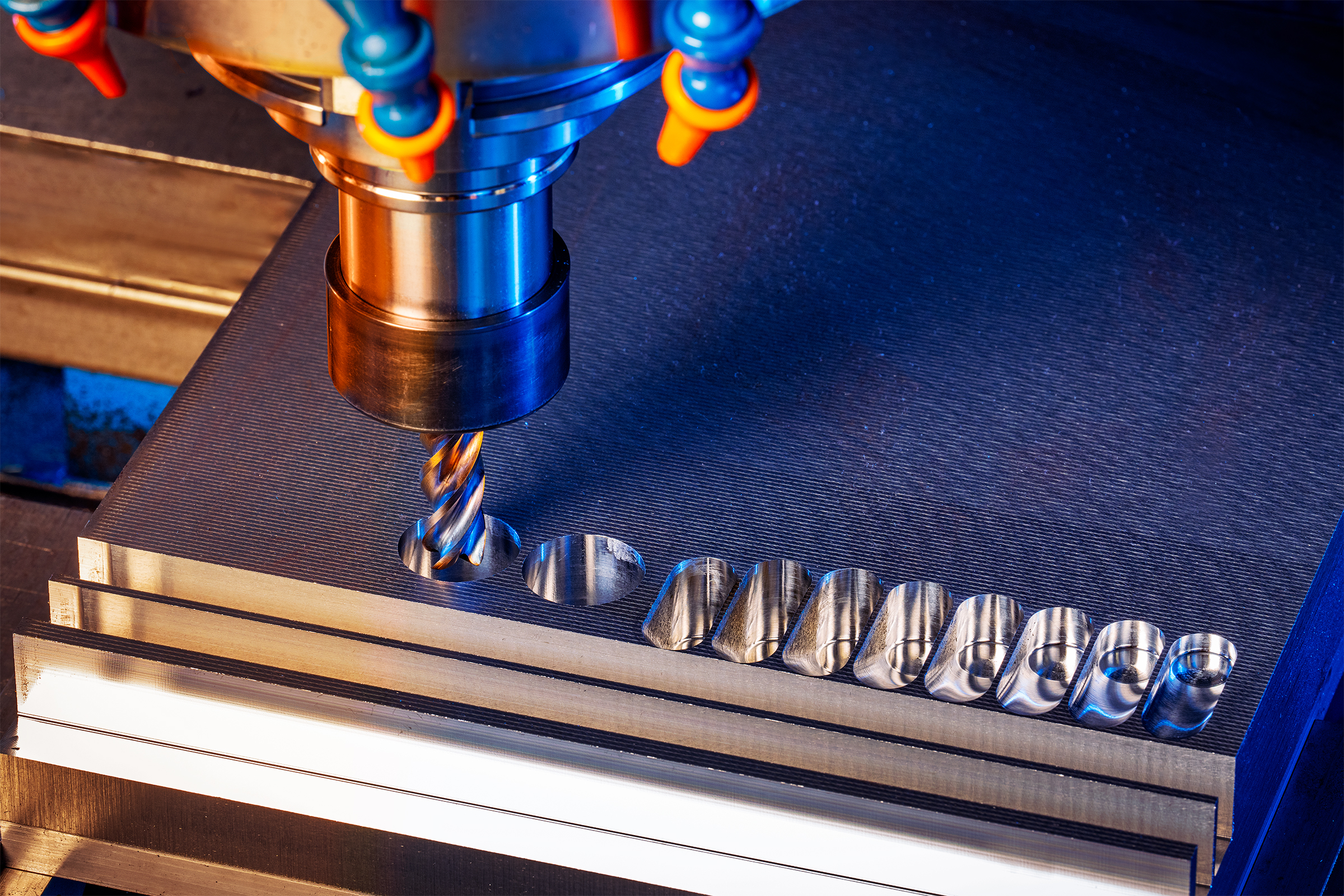

IMCO Carbide Tool has introduced the POW-R-FEED M934, a 4-flute end mill designed to enhance machining efficiency across a range of materials, including steel, titanium, plastics, brass, bronze, and aluminum. The M934 end mills feature an optimized flute and core design, aimed at improving chip evacuation and supporting high-efficiency machining (HEM) tool paths in 3- to 5-axis machines.

"This extension of the POW-R-FEED M9 series was developed to help manufacturers achieve higher productivity," said Matt Osburn, Vice President, Technical Director at IMCO. "The M934 end mills offer improved chip flow, reduced downtime, and enhanced ramping and helical entry capabilities."

Performance and Design Features

The M934 end mills are engineered to support a variety of machining operations, including aggressive cuts and complex tool paths. Their flute geometry and AlTiSN coating are designed to facilitate smooth cutting action, maintain high speeds, and optimize metal removal rates.

"With 20-horsepower, 40-taper machines, the M934 end mill maximizes output," said Steve Avers, IMCO's Technical Support Manager. "The free-cutting design helps maintain cutting speed while ensuring efficient chip evacuation, which supports high-speed machining and increased part production."

The M934 cutters incorporate a carbide core with fine cutting edges and a wiper flat end for improved surface finishes. Additionally, edge preparation is designed to extend tool life.

Availability and Pricing

The POW-R-FEED M934 end mills are part of IMCO's POW-R-FEED M9 series and are positioned as a cost-effective alternative to other high-performance cutting tools.

For more information about the POW-R-FEED M934 end mills, contact IMCO at 1-800-765-4626 (USA) or 419-661-6313 (international), or visit www.imcousa.com.