Contact Details

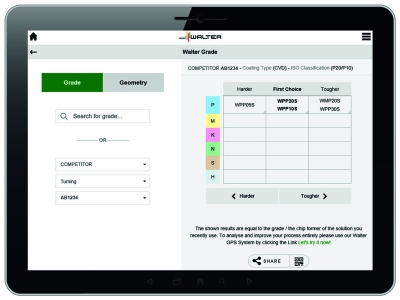

Walter has developed the Insert Converter app, which quickly shows the insert selection with the latest Walter grades and chipbreaker geometries for an application. It is aimed at anyone who wants to enhance their machining process, increase tool life and process reliability, or improve their productivity.

The app’s search function has been deliberately kept simple: Users do not have to click through endless menu options. Instead, they can make selections directly based on the grade or geometry. To do this, they enter the grade or chipbreaker geometry already in use – and the app then shows them Walter alternatives. The recommended grades or geometries may vary considerably depending on the workpiece material. If required, the user can click for additional detailed information on the coating process (CVD/PVD, etc.) or basic ISO shape (positive/negative). In the case of ISO geometries, the indexable insert style (single or double-side, negative, etc.) is also displayed.

In addition to carbide cutting tool materials, ISO advanced materials such as CBN, PCD, ceramic and cermet are also covered. The range of applications includes turning, grooving and parting off. When developing the Insert Converter app, Walter focused on practical applications and user friendliness, so it is compatible with both Android and iOS (Apple) devices.

It is also available as a web version via a browser – and offline, if required. The Walter Insert Converter app can be downloaded from the App Store, Google Play or Walter's website.

Related Glossary Terms

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- cutting tool materials

cutting tool materials

Cutting tool materials include cemented carbides, ceramics, cermets, polycrystalline diamond, polycrystalline cubic boron nitride, some grades of tool steels and high-speed steels. See HSS, high-speed steels; PCBN, polycrystalline cubic boron nitride; PCD, polycrystalline diamond.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- indexable insert

indexable insert

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

- polycrystalline diamond ( PCD)

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.

PRODUCTS

PRODUCTS