Contact Details

BIG KAISER has released a new set of insert grades for its indexable tools—C-Cutter Mini, C-Centering Cutter and Fullcut Mill. The new inserts are optimized to extend tool life in stainless steel or aluminum.

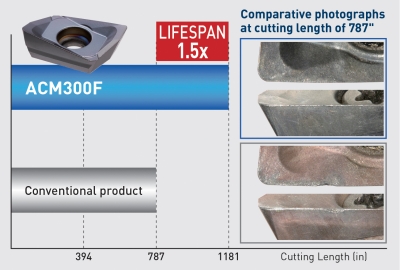

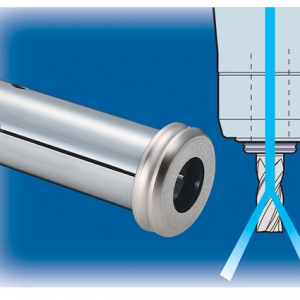

Suited for peck-drilling, ramping, helical and shoulder milling, the Fullcut Mill is now available with the PVD-coated carbide ACP300 with nanometer-level thickness and ultra-multilayered TiAIN and AICrN film, replacing the ACZ350S for general steel applications. The new ACM300F is designed specifically for stainless steel work. The ACM300F boasts excellent fracture and welding resistance and has demonstrated a lifespan 1.5 times of conventional inserts in testing.

The new ACM250F stainless steel grade can be used for chamfering and spot drilling with the C-Cutter Mini or C-Centering Cutter. PVD-coated carbide with excellent smoothness, the new grade resists welding and chipping due to the ultra-multilayered thin film structure made of AlTiN and TiAlCrN. The ACM250F replaces the ACZ150 used with the C-Centering Cutter.

The DS20 for aluminum/nonferrous metals is available for the first time for the C-Centering Cutter. Its diamond-like DLC coating is ultrasmooth with a low wear coefficient and superior welding resistance, and effectively prevents burrs.

Related Glossary Terms

- chamfering

chamfering

Machining a bevel on a workpiece or tool; improves a tool’s entrance into the cut.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

PRODUCTS

PRODUCTS