Contact Details

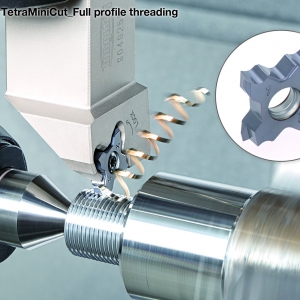

Tungaloy has done it again. Its latest KKH cartridge modules for SwissBore digital fine boring tool system make all fine boring operations, whether using SwissBore tooling or not, digital ready.

SwissBore digital fine boring tool system covers a diameter range from 9.75 mm (.384″) to as large as 2,000 mm (78.740″) with the use of the extension bridge. The system integrates the Quick-Change coupling solution that contains an extensive range of boring heads, adapters, extensions, and holders with connections based on HSK40/63/100, PSC-C6, MAS-BT30/40/50 and more. This ensures maximum machine utilizations with minimum measuring, setup, and tool changing time for most multi-tasking machines and turning centers.

KKH cartridge modules take all customized fine boring tooling, whether they are designed by SwissBore or not, and turn them into a state-of-the-art fine boring solution that have one thing in common: they are all digital ready. The cartridge modules allows both radial and axial adjustments. Radial adjustments are possible without influencing axial position, making fine adjustments of the cutting edge position exceptionally efficient and precise.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS