LASORTING for Cutting, Sorting and Storage of Sheet Metal

LASORTING for Cutting, Sorting and Storage of Sheet Metal

Recently acquired by Mitsubishi Electric Corp., ASTES4, a company based in Switzerland, specializes in the development of automated sorting solutions for sheet metal laser processing machines. ASTES4 has developed LASORTING – the first fully integrated system for the cutting, sorting and storage of sheet metal to streamline processes, speed up production and reduce labor costs.

Recently acquired by Mitsubishi Electric Corp., ASTES4, a company based in Switzerland, specializes in the development of automated sorting solutions for sheet metal laser processing machines. ASTES4 has developed LASORTING – the first fully integrated system for the cutting, sorting and storage of sheet metal to streamline processes, speed up production and reduce labor costs.

Due to this acquisition, as an established automation solution partner for Mitsubishi Electric, MC Machinery customers now have direct access to premium sorting solutions for laser automation needs like LASORTING.

To work efficiently, laser-cutting systems need a swift supply of material and subsequent sorting.

"The entire industry is trying to move in the direction of part sorting, and we've seen a lot of excitement surrounding the capabilities of LASORTING," says Jason LeGrand, automation specialist at MC Machinery. "This is essentially a smart robot, it knows what the part is, the right measurements and where it belongs. With unmanned operations human error is eliminated, and it is a safer solution since parts no longer have to be detached from the skeleton and sorted by hand – dramatically reducing accident risks from the handling of heavy loads."

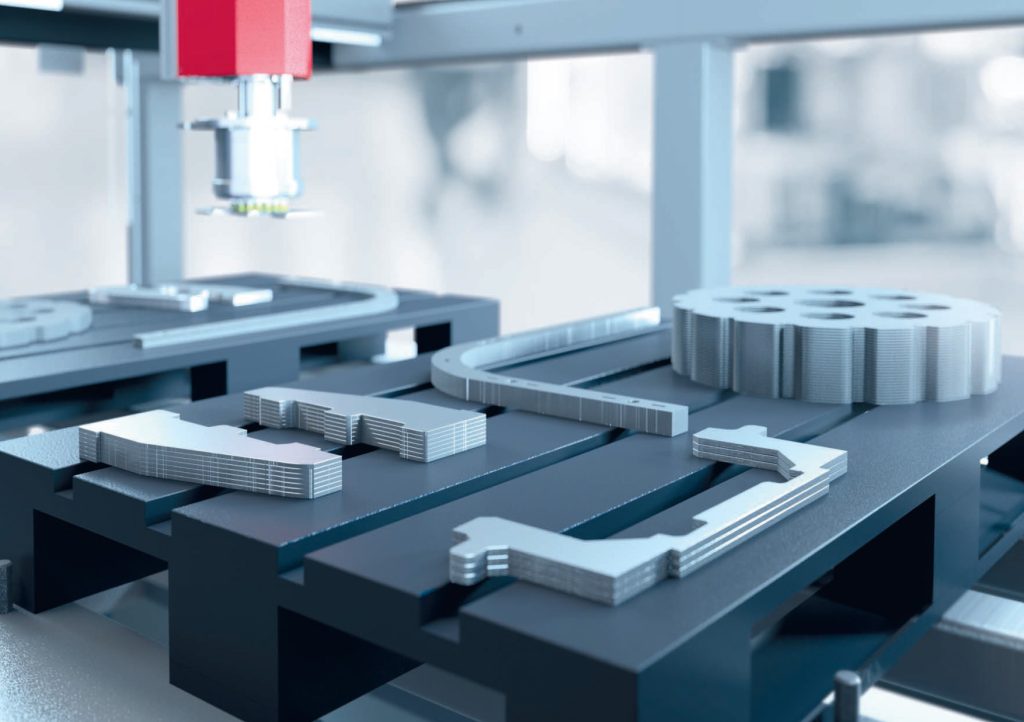

The laser-cutting systems for LASORTING are designed to operate dependably, efficiently, and with the highest cutting quality. They are capable of processing sheets measuring 3 x 1.5m and 4 x 2m in an output range of 2kW to 8 kW. With four sorting heads, each independent head is capable of lifting 1,100 pounds and has a maximum speed of 9,600 inches a minute.

"When putting in raw steel sheets, what comes out on the other end are perfectly stacked and organized parts already on pallets ready for wrapping and shipping or to go to the secondary operation," says LeGrand. "A fully automatic warehouse with a sorting system ensures optimum materials flow and continuous processes."

The system is highly configurable to fit many different shop floors. Thanks to its modularity, LASORTING's production cell adapts to a customer's production requirements and space available on site.