LUMICLAD Black-Oxide Finish

LUMICLAD Black-Oxide Finish

The LUMICLAD finish from Birchwood Technologies forms a nearly non-dimensional black oxide finish on all aluminum surfaces. LUMICLAD is very durable, clean and tightly adherent to the metal substrate.

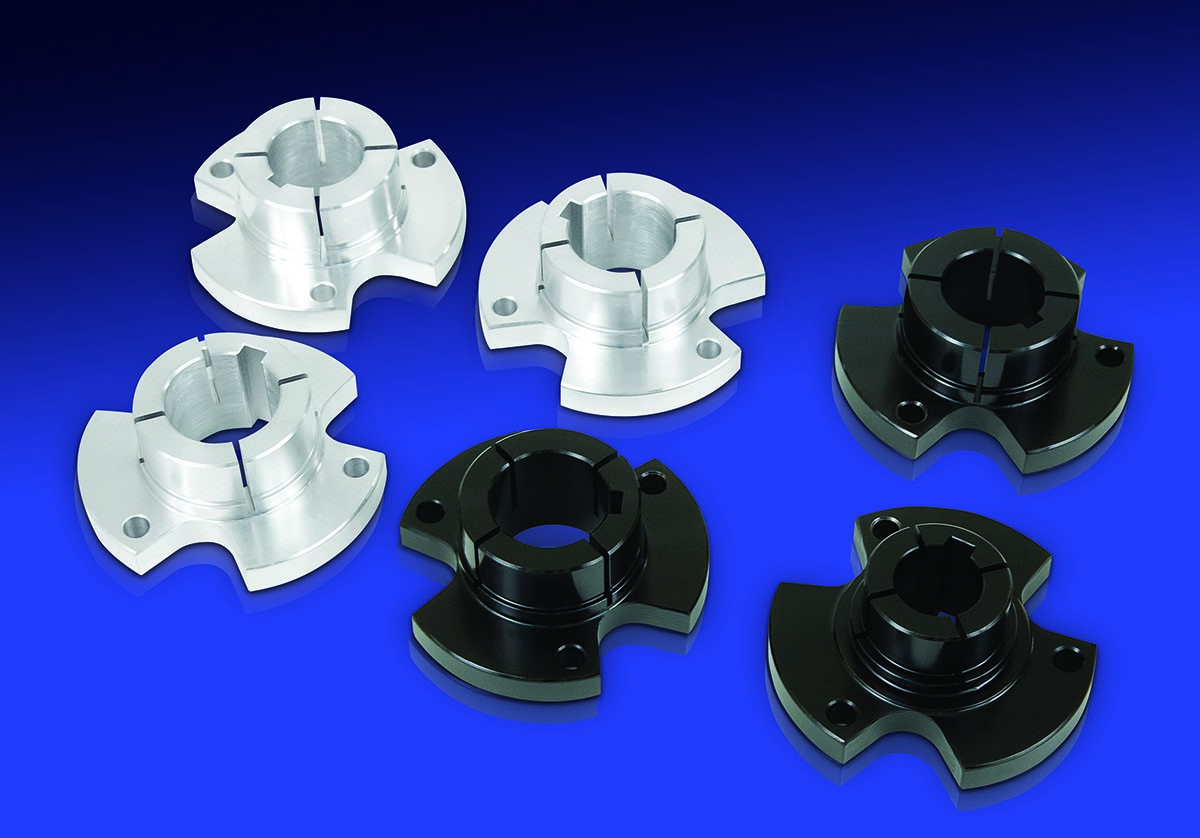

The LUMICLAD finish from Birchwood Technologies forms a nearly non-dimensional black oxide finish on all aluminum surfaces. LUMICLAD is very durable, clean and tightly adherent to the metal substrate. The LUMICLAD process produces a uniform coating thickness of .000060 inches (1.5 micron) that will not close down hole diameters or change critical part dimensions. The smooth black finish has a slightly porous crystal structure that absorbs an optional topcoat such as a dry-to-touch sealant, light oil, or clear polymer.

The LUMICLAD aluminum blackening process from Birchwood Technologies produces a rich black finish on aluminum components and is ideal for power transmission components such as couplings, electrical card cages, and military and weapon components. Lumiclad is also electrically conductive and provides predictable chassis grounding in desired products.

By utilizing a conventional immersion seven-tank process line, the LUMICLAD process is easy and safe to operate so that manufacturers can operate it in-house. Short process cycle takes just 30 minutes. This process can be utilized for jobs of any size component, large or small, and for large quantities of smaller parts. Parts can be finished on racks as well as in baskets or barrels without the need to individually clamp each part, and the process is electroless so no individual racking is necessary.