Contact Details

Tungaloy is introducing the M714B T-CBN grade for finish machining of heat-resistant superalloys. M714B contains submicron sized fine CBN grains and alumina as a binder providing the grade with high thermal stability. This composition enables high speed applications in Ni-base superalloys such as Inconel 718, ensuring higher machining efficiency than conventional grades. The grade’s uniform matrix of CBN and binder provides high surface finishing quality at high cutting parameters.

Manufacturers of critical components for aerospace industries face strict requirements of finished surface integrity as process security and quality are of utmost importance. The new M714B grade is available in two styles of edge preparations optimized for maximum surface integrity: LS offers a lightly chamfered and honed cutting edge commonly found in PCBN inserts intended for HRSAs; while E style provides a lightly honed cutting edge where low cutting forces are essential. M714B offers cutting edge preparations that are tailored to optimize performance in the targeted areas, while also enabling process security and efficiency in high temperature and high cutting speed conditions.

At a glance:

High thermal stability enables high-speed machining with exceptional wear resistance

Available in two types of edge preparations: “LS” with a light chamfered and honed edge, while “E” offers a lightly honed cutting edge

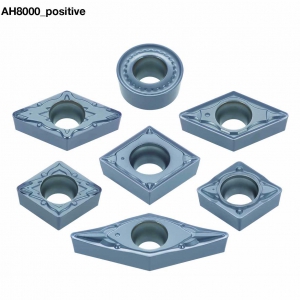

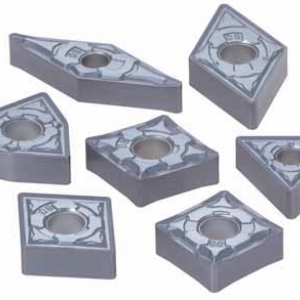

Total of 24 inserts to be introduced

Related Glossary Terms

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- polycrystalline cubic boron nitride ( PCBN)

polycrystalline cubic boron nitride ( PCBN)

Cutting tool material consisting of polycrystalline cubic boron nitride with a metallic or ceramic binder. PCBN is available either as a tip brazed to a carbide insert carrier or as a solid insert. Primarily used for cutting hardened ferrous alloys.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS