Machining Strategist V13.0

Machining Strategist V13.0

Vero Software announced the release of Machining STRATEGIST V13, a powerful multi-axis CAM solution that generates optimum HSM roughing and finishing CNC toolpaths for both the office and shop-floor environment.

Vero Software announced the release of Machining STRATEGIST V13, a powerful multi-axis CAM solution that generates optimum HSM roughing and finishing CNC toolpaths for both the office and shop-floor environment. STRATEGIST is a CAD independent solution and can work with data from all major 3D modelling systems. Within the latest release, support for VISI 19 has been included and the CAD interfaces have been aligned to Parasolid v24, SolidEdge ST4 and Catia v5 r21.

Significant product enhancements include a number of new machining algorithms that will greatly benefit both Machining STRATEGIST customers and OEM partners.

New CAM developments include:

HM Waterline Passes — A finishing strategy that combines all the benefits of a traditional waterline operation with a 3D pocketing routine that interacts with the main strategy whenever the shallow area between consecutive passes allows the insertion of additional passes. This method allows an optimal finish over the entire part, helping to extend tool life and produce parts with excellent surface finish.

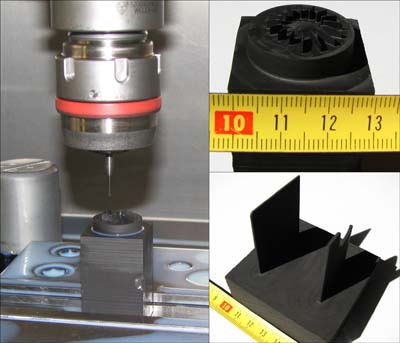

HM Rib Machining Passes — A new strategy especially designed to machine very thin walls. These walls are often made from exotic materials (such as titanium for aerospace), and therefore a traditional approach to their machining is often difficult and risky, specifically towards the end of the process when the rib is subjected to high frequency vibrations and micro-flexes. This new strategy combines a new roughing toolpath and a finishing strategy to create a unique toolpath that should preserve the highest possible part rigidity.

Further product enhancements include improvements to Helical passes, calculation speed improvements for non-smoothed waterline passes and the ability to define different feedrates within Rest Machining and Combined Waterline for steep and shallow and offset passes.

Steve Youngs, MS Development Manager concludes, "The Machining STRATEGIST development cycle is driven by customer needs, and an ever increasing requirement to have complete toolpath control when programming complex parts. The Vero development team strive to keep our customers at the leading edge of technology with new CAM algorithms and the intelligent use of multi-threaded background processing."